LG-X Series Magnetic Fuel Conditioners

LG-X Series Specifications

& Frequently Asked Questions

Inline Fuel Conditioners Specifications (1)

Port Size

Max. Flow Rate (On Engine) (2)

Weight (lbs)

Horse Power Range (hp) (2)

Model: LG-X 200

1/4″ NPT Thread (3)

1 to 25 GPH (3.8 to 95 LPH

1 lb (0.45 kg)

Up to 200 hp (Up to 149 kW)

Model: LG-X 500

1/2″ NPT Thread (3)

20 to 110 GPH (76 to 417 LPH)

2 lb. (0.9 kg)

Up to 500 hp (Up to 373 kW)

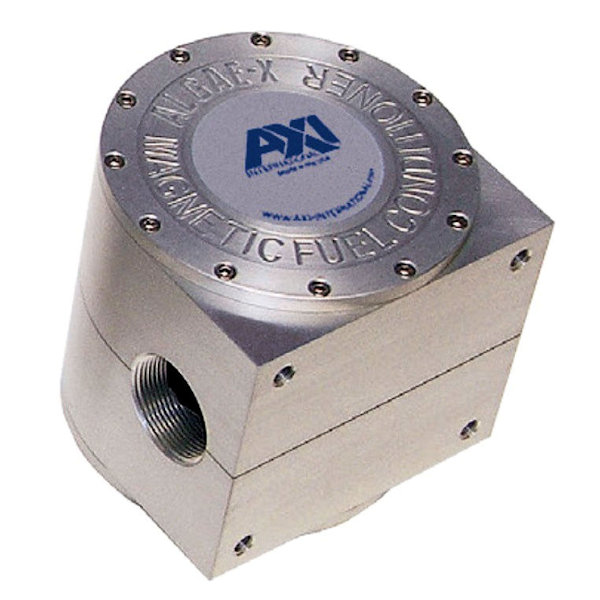

Model: LG-X 1500

3/4″ NPT Thread (3)

50-350 GPH (189 to 1,325 LPH)

3.5 lb (1.6 kg)

Up to 1,500 hp (Up to 1,118.5 kkW)

Model: LG-X 3000

1″ NPT Thread (3)

200 – 800 GPH (757 to 3,028 LPH)

7.5 lb (3.4 kg)

Up to 3,000 hp (Up to 2,237.1 kW)

Model: LG-X 4000

1-1/2″ NPT Thread (3)

1,500 GPH (5.678 LPH)

35 lbs (12 kg)

3,000 hp and up (2,237.1 kW and up)

Model: LG-X 5000

2″ NPT Thread (3)

2,500 GPH (9,464 LPH)

35 lbs (16 kg)

3,000 hp and up (2,237.1 kW and up)

(1) Larger capacity equipment for higher flow rates available.

(2) Max recommended flow capacity for engine applications. For recirculating systems double the indicated flow rate.

(3) NPT designates that the Magnetic Fuel Conditioner is drilled and tapped for National Pipe Thread fittings. BSP Threads (British Standard Pipe Thread) adapers (BSP Female to NpT Male) kits are available for installations up to 1 inch where the installation is to use BSP threaded fittings. Order the proper kit for the fittings that are need for your installation.

Material: Anodized Marine Grade corrosion resistant 6061 Aluminum.

AXI does not market or sell the LG-X Series Fuel Conditioner as a gadget that will provide you with a great improvement in fuel economy by simply adding this component to your equipment. That being said, what we do sell to our customers is a component that, when added to equipment that suffers from clogged and slimy filters, dark, hazy fuel, floating debris in tanks, sludge build-up in tanks, loss of power and RPM, excessive exhaust smoke, corroded, pitted fuel injectors, or a foul odor emitting from the fuel tank, all symptoms of having “Bad Fuel”, the addition of an LG-X Series Fuel Conditioner will reverse the fuel degradation, and with the adoption of a few simple steps to prevent water entry into, and water accumulation in your fuel tank, regular circulation of the stored fuel through the LG-X Fuel Conditioner, and performing regular engine maintenance recommended by the equipment manufacturer, your fuel problems will be but a memory, your equipment will run better and last longer.

As long as fuel meets the (ASTM) specifications and engine manufacturer stated requirements, it will perform in your engine and the LG-X Series Fuel Conditioner will not improve upon that. Using fuel that is less than optimal quality negatively impacts engine efficiency and accelerates the process that degrades fuel injectors, causes fuel pump failure, and makes new engines old. LG-X Series Fuel Conditioners are an excellent preventative maintenance step that will keep the fuel in your equipment in optimal condition.

The solution to suspected microbial growth and the results of asphaltene agglomeration in your fuel is the application of LG-X Series Fuel Conditioning Technology. Fuel Conditioners, when installed in-line in your equipment fuel system, will reverse the process of fuel breakdown, prevent microbial growth, restore fuel filterability, enhance combustibility, and prevent clogged filters and tank sludge. Optimizing fuel droplet size results in combustion efficiency, improved filterability and lower operating costs. (For a detailed explanation of how the LG-X Series Fuel Conditioner performs, see the web page “Learn More About Magnetic Fuel Conditioning”)

The LG-X Series Fuel Conditioner will also disperse and return to solution the asphaltene clusters the result in stored fuel degradation and return the fuel to a clear and bright appearance, a process sometimes referred to as “Fuel Polishing”. (For additional information, see “Diesel Fuel Polishing”)

Operating on the principle of induction on the process of combining kinetic and magnetic energy to influence the behavior of electrons, the LG-X Series Fuel Conditioner provides a powerful magnetic field and the flow of fuel provides the kinetic energy. The process of how the LG-X Series Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling.

As the LG-X Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the LG-X Series Fuel Conditioner. However, there are situations where the benefit of circulating your fuel through a magnetic unit has added benefit. Should the LG-X Series Fuel Conditioner be used in a situation where a fuel tank itself is in poor condition, where the tank may be rusted on the inside and rust flakes may be coming loose, the LG-X Series Fuel Conditioner would prevent the sharp metal flakes from progressing to the fuel filter where they may pierce the filter medium and allow unfiltered fuel to proceed to the fuel system. Also, should the source of your fuel be questionable, such as a marine vessel that fuels at island fuel stops with little oversight, or remote mining operations where a supplier may not be reliable, having the LG-X Series Fuel Conditioner installed to stop metal shavings or other ferrous debris that may be the result of maintenance on upstream distribution equipment could be a great benefit.

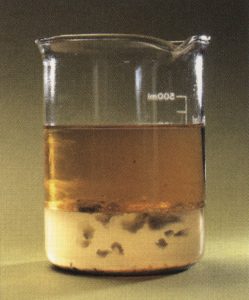

Should a fuel restriction that cannot be traced to a clogged filter element make the LG-X Series Fuel Conditioner suspect, you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. An extreme example is pictured to the left. A spare parts kit for the LG-X Series Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

To completely reverse the buildup of particulates and fuel components that have attached themselves to the fuel tank bottom and sides, the fuel system lines, and inside surfaces of engine components, combine the use of the LG-X Series Fuel Conditioner with regular use of AFC Series Fuel Catalyst and Tank Cleaning Additives. Unlike off-the-shelf additives that lubricate the fuel pump and limit their effectiveness to cleaning the injectors, the LG-X Series Fuel Catalyst and Tank Cleaning Additives reverse the long term buildup of sludge and degraded organic materials that have accumulated over time in the tank bottom, removes carbon buildup from engine components and stops the degradation of fuel injectors caused by the acids and degraded fuel components.

As diesel engines operate, excess fuel not used for combustion is returned to the tank. This process results in a continuous re-circulation of the fuel from the tank through the fuel system, and back to the tank that allows the Fuel Conditioner to continuously maintain the fuel in optimal condition for peak engine performance. The LG-X Series Fuel Conditioner, installed in the fuel line between the fuel tank and the primary filter, continuously treats the fuel and keeps the entire system clean while the equipment operates.

The type of application where this works ideally is where equipment is used for a period of time at least several times each week. The following is a list of some of the applications where an LG-X Series Fuel Conditioner installed on the fuel line will continuously keep the fuel in optimal condition:

- Tractor Trailer rigs

- Commercial Trucks of all kinds

- Diesel Pickups

- Marine vessels used regularly

- Construction Equipment used year around

- Mining Equipment used year around

- Diesel Locomotives

- Equipment rented out year-around

- Farm equipment used year-around

- Diesel power generators that provide primary power (off-the-grid power) year-around

In applications where the diesel engine is not operated for weeks or months at a time and, as a result, the fuel is not circulated on a regular, extended basis, the fuel will not be treated and the fuel will again deteriorate.

The LG-X Series Fuel Conditioner only does its work when the fuel is circulating. The following are examples of applications where a Fuel Conditioner that is mounted in-line on the fuel feed line to the engine is not appropriate:

- Power Generators used only when the primary electricity service fails

- Marine vessels that are not used for months over the winter season

- Construction Equipment that is special purpose and not used very often or sits idle during certain seasons

- Rental equipment that is rented only occasionally

- Farm equipment used seasonally or only during harvest

- Trucks or other equipment used to backup front-line equipment and sit idle for long periods

- Fuel Tanks that service Primary Power generators at resorts or hunting/fishing lodges that operate on during certain seasons and sit idle the rest of the year

- Fuel Tanks that service fuel needs in seasonal operations

For these applications, we offer designed systems to specifically meet the needs of your application. Equipment that requires periodic Fuel Treatment and Tank Cleaning may be best serviced by one of the following:

Although horsepower and flow rating information for each LG-X Series Fuel Conditioner is provided in the table along the left side of this page, the easiest means of choosing the proper size unit of your application is to determine the inside diameter of the fuel line that you intend on mounting the LG-X Series Fuel Conditioner on. If the inside diameter of the fuel line is a size for which there is no unit, use the next larger size unit. Using an LG-X Series Fuel Conditioner that is smaller than the inside diameter of your fuel line may cause a fuel flow restriction, especially at high rpm operations.

The LG-X Series Fuel conditioner is available in all sizes with National Pipe Thread (NPT), commonly used in North America. In portions of the world where British Standard Pipe thread (BSP) is used, you should purchase the correct LG-X Series Fuel Conditioner that is listed as equipped with BSP threaded adapters. Please order the appropriate version of the Magnetic Fuel Conditioner needed for the pipe standards in your country. Note that when fulfilling an order for a Magnetic Fuel Conditioner with BSP threads, we will ship an NPT threaded Magnetic Fuel Conditioner with adapters that allow for use of the unit with BSP threaded fittings.

The LG-X Series Fuel Conditioner is bi-directional. Either port may be used as the in-port or out-port. They are easily installed in the fuel line between the tank and the primary filter.

First, turn off the engine or circulating pump and close the necessary valves to assure that any cutting of the fuel line does not cause fuel to run from the tank or the engine side of the cut. Install the LG-X Series Fuel Conditioner unit in the fuel system exclusively using connectors and fuel line of appropriate diameter, material and quality as recommended by the engine manufacturer. Apply fuel resistant sealant to all connectors and (if applicable) to the bleeder screw on the face of the LG-X Series Fuel Conditioner. Check as necessary to make sure all fittings are properly tightened and no air is allowed to be enter the fuel line or the LG-X Series Fuel Conditioner after installation.

Use a pliable, non-hardening, Diesel Fuel Resistant paste or gasket forming sealant on threads. When using Teflon tape make sure it is resistant to diesel fuel and oil as some of these products are primarily designed for water applications.

The LG-X Series Fuel Conditioner is mounted either horizontally or vertically, but NOT with the round side of the unit facing down. We recommend to NOT use 90 degree elbows or sharp curves when installing the LG-X Series Fuel Conditioner in the fuel line. Properly installed LG-X Series Fuel Conditioners will not cause a pressure drop within the recommended flow capacity range.

After installation, check to insure that all connectors are tight and secure. Use bleeder screws (if included on the model being installed) on the LG-X Series Fuel Conditioner, as well as on filters and pumps to bleed all air out of the fuel system, and again check for fuel and/or air leaks. Your LG-X Series Fuel Conditioner is now ready for a lifetime of trouble-free service.

The magnet in your LG-X Series Magnetic Fuel Conditioner is a permanent magnet. The unit is Direct Flow-Through, Self-Cleaning and requires virtually no maintenance. As long as the unit is not abused, dropped, or damaged, the unit will continue to function normally.

At times, metal fuel tanks will rust and ferrous metal type debris may come into a tank from a fuel fill-up or other means. Any metals that can be drawn to a magnet that may enter your fuel line could stick to the magnet. This is not bad in that it will stop any such metal from passing through your filters, damaging pumps and injectors. This will become evident if you develop a fuel restriction and have the resultant loss of power, usually at high rpm. Should this happen, remove the screws from the face-plate, taking care not to damage the O-ring that seals the face-plate to the main body of the unit. Carefully wipe the metal debris off the magnet with a shop rag and replace it into the body of the unit, and reattach the face plate. Be careful with the magnet in this operation as it is brittle and hitting the magnet on a hard object or dropping the magnet will break the magnet. This breaking of the magnet is not covered under the AXI warranty. Take care to not over-tighten the face plate screws. Bleed the unit if necessary to remove any air.

You may experience after some years of operation a problem with the O-ring degrading and allowing a leak of fuel from around the face-plate or performance issues resulting from air leaking into the fuel line as a result of the degraded O-ring. You will note that we sell parts kits for all LG-X Series Fuel Conditioners that include a new O-ring and new screws for the use in this maintenance task.

Clogged Filters, Dirty Tanks?

Frequent Filter changes and incurring the expense and inconvenience of cleaning fuel tanks have become acceptable periodic maintenance instead of a warning signal for engine failure. Filter elements should last a thousand hours or more, and injectors some 15,000 hours. However, since diesel fuel is inherently unstable, solids begin to form and the accumulating tank sludge will eventually clog your filters, ruin your injectors and cause engines to smoke. LG-X Magnetic Fuel Conditioners have overcome these and other issues in applications where fuel is stored or used.

Fuels and oils are susceptible to natural deterioration, like any other organic fluid. Oxidation, chemical incompatibility, water and microbial infestation all contribute to the process of polymerization and stratification of diesel fuel and other hydrocarbons. This results in poor Fuel Quality, and the formation of tank sludge, bio film and acids. These by-products of the process of fuel breakdown cause clogged filters, corroded injectors, pumps and tanks, incomplete combustion (evident from black smoke, caused by un-burned fuel, from the exhaust), carbon build-up on internal engine components, and loss of power. As these problems build on each other, these individual symptoms of bad fuel ultimately lead to complete engine failure.

Degraded Fuel Shortens Filter Life

and Hurts Engine Performance

Doing What Filters and Chemicals Can’t

Filters, separators, and centrifuges remove particles and free water from fuel. Biocides, commonly recommended by many mechanics to cure the ills of “algae” in fuel tanks, are really less than effective in the long term control of microbial activity. Neither, however, eliminates fuel instability or sludge buildup in tanks. Biocide treatments aggravate filtration problems by turning bio-sludge into solids. Removal of fuel tanks for cleaning with high pressure washers or steam (a favorite recommendation of equipment dealers) is expensive, takes equipment out-of-service, necessitates the removal and disposal of fuel from tanks, and is likewise ineffective and does not provide a long term solution.

A study by the University of Idaho determined that there could be as much as a 26% degradation in diesel fuel after just 28 days of storage.

Spare Parts Kits (replacement o-ring and new screws) for all Fuel Conditioners and BSP Thread Adapters for use with select Fuel Conditioners are available — See Bottom of this Page

Diesel Fuel is Inherently Unstable

Diesel engines continuously return fuel not used for combustion back to the tank. The repeated exposure to the heat and pressure of the injection system accelerates this breakdown of fuel quality. Fuel quality and fuel chemistry is affected by transportation, storage tank conditions as well as length of time in storage, and factors such as oxidation, water in the fuel, microbial contamination (contributing to acid formation), and incompatibility of fuel additive packages with after-market additives, etc. This toxic combination negatively impacts: (i) the filterability of the fuel through filters that become clogged; and (ii) causes a dramatic increase in the size of the fuel droplets emitted from the fuel injector into the combustion chamber. The degraded condition of the fuel, when combined with the injector degradation that occurs over time from the use of the degraded fuel, result in fuel not being completely burned in the combustion chamber causing the formation of carbon deposits on internal engine components, all evidenced by a noticeable increase in smoke from the exhaust, loss of power, and an increase in fuel consumption. (See “Diesel Fuel & Injector Failures” for additional information)

Dark, Ugly Fuel

Diesel Fuel suffers from a perplexing problem with a natural tendency to degrade over time. This process can begin within six months of the time the fuel leaves the refinery and is aggravated by the high-pressure that fuel is subjected to in todays fuel injection systems. The extreme pressure and heat of these systems results in the agglomeration of asphaltenes present in the fuel, the high carbon content heavy end fuel molecules that are in solution when the fuel exits the refining process. Asphaltene agglomeration leads to the formation of larger and larger clusters and solids, which are very difficult to completely combust. They contribute to the degradation of injector spray patterns as injector orifices become partially or totally blocked. As fuel spray patterns become compromised, combustion of the fuel becomes incomplete, resulting in increased exhaust smoke and carbon build up on internal engine components. These solids grow so large that they will not pass through the filter element. They become part of the polymer and sludge build up plugging the filter.

Diesel Fuel suffers from a perplexing problem with a natural tendency to degrade over time. This process can begin within six months of the time the fuel leaves the refinery and is aggravated by the high-pressure that fuel is subjected to in todays fuel injection systems. The extreme pressure and heat of these systems results in the agglomeration of asphaltenes present in the fuel, the high carbon content heavy end fuel molecules that are in solution when the fuel exits the refining process. Asphaltene agglomeration leads to the formation of larger and larger clusters and solids, which are very difficult to completely combust. They contribute to the degradation of injector spray patterns as injector orifices become partially or totally blocked. As fuel spray patterns become compromised, combustion of the fuel becomes incomplete, resulting in increased exhaust smoke and carbon build up on internal engine components. These solids grow so large that they will not pass through the filter element. They become part of the polymer and sludge build up plugging the filter.

If you have noticed diesel fuel that has been in storage having an appearance of dark brown or even black, then you have witnessed the agglomeration of this asphaltene component as it comes out of solution. As these clusters increase in size and gain weight, they will drop to the bottom of the fuel tank and, in time, accumulate into a dark mass. If you have inspected a fuel tank and noticed what looks like the bottom of the tank has been painted with roofing tar, then you have seen the result of this fuel degradation process.

Review the Frequently Asked Questions to the left to understand more about how Magnetic Fuel Conditioning can solve your problems with stored or degraded diesel fuel.

Additional Steps to Fuel Management

The LG-X Fuel Conditioners do a great job of maintaining the diesel fuel for optimal performance and efficiency. But if water is getting into your fuel tank, it can accumulate to the point that water will get to your engine and create havoc with your fuel pump and injectors.

Most fuel tanks have the fuel pick up line placed so that fuel is drawn from the fuel tank slightly above the bottom of the tank. This placement can be as little as one inch above the tank bottom, or up to several inches. However, many applications, such as marine craft and mobile equipment, especially in the construction industry, have so much movement, the fuel cannot help but slosh around in the tank.

This extreme movement prevents the placement of the fuel pickup line from preventing water that has accumulated in the tank from entering the fuel line. Capturing and removing water that would otherwise get into the tank is a critical component of fuel management.

The best defense in preventing the water from damaging engine components is a good offense.

Consider seriously taking steps to prevent water from getting into the tank. The most common means of water entry is through the tank breather vent. As fuel is drawn out of the tank, the area above the fuel is replaced by air drawn in through the tank vent. The air drawn into the tank contains moisture (in certain locations, a lot of moisture) as well as airborne debris, pollen, and fungi.

The moisture condenses on the walls of the tank as the temperature changes. This water accumulates in the tank bottom. This process contributes greatly to fuel quality problems.

The moisture condenses on the walls of the tank as the temperature changes. This water accumulates in the tank bottom. This process contributes greatly to fuel quality problems.

Using a Desiccant Breather Filter that is designed to incorporate Desiccant material to capture and hold moisture, along with a one micron air filter to capture and prevent debris and particulates from entering your fuel tank is a critically important defensive step.

Without an accumulation of water, microbial and fungi growth is prevented. The Desiccant Breather prevents the accumulation of water, which is the habitat in which the microbial contamination lives and reproduces. Microbes are eventually consumed by engine combustion.

The Desiccant material consists of crystals that absorb and hold the moisture. The Desiccant material expands and changes color from blue to pink as moisture accumulates, signaling that the breather has absorbed its capacity of moisture and requires replacement.

But not all water comes in through the breather. Water can and does come into the fuel tank with the fuel. You are exposed to the results of how upstream fuel storage tanks have been miss-managed with every fuel fill.

But not all water comes in through the breather. Water can and does come into the fuel tank with the fuel. You are exposed to the results of how upstream fuel storage tanks have been miss-managed with every fuel fill.

This is especially problematic when the fuel is biodiesel as biodiesel has the ability to absorb more moisture than fossil diesel. (See article published by the University of Idaho BIOdiesel Tech) The solution is using the Water Eliminator fuel tank water remover.

This handy little solution is a cylindrical container that contains Desiccant material. Place the Water Eliminator in the tank, using the supplied lanyard to retrieve it for periodic inspection. The water specific Desiccant material absorbs water that has accumulated in the fuel tank while it lies on the tank bottom. When the Desiccant material swells up with absorbed water, remove it from the tank and replace it with another Water Eliminator.

Maintaining optimal fuel quality assures your fuel provides the most efficient operation and extends the life of critical engine components, thereby reducing your cost of operation and maintenance. Preventative maintenance has proves its worth over and over again.

Spar Parts Kits include an O-ring to seal between the face plate and the body of the Fuel Conditioner and new screws to fasten the face plate (except for the Kit for the LG-X 5000 that does not include the screws)

The LG-X Fuel Conditioners are drilled and threaded with NPT Threads. The below are adapters for use on LG-X Fuel Conditioners in applications where BSP thread connections are required.