STS 7000 Series Enclosed Automated

Fuel Cleaning & Maintenance Systems

Polish Your Fuel -- It's Too

Late When The Lights Go Out

STS 7000 Series

Component Descriptions & Specifications

STS 7003 Enclosed Automated Fuel Maintenance Systems

Flow Rate

180 GPH (681.4 lph)

Serviceable Tank Size

500 to 4,000 gallons (11,400 to 22,700 ltr)

Motor

1/3 HP single phase, continuous duty, thermally protected

Pump

Spur Gear Pump

Power

120V / 60Hz / 15A or 230V / 50Hz / 15A*

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Plumbing

Black Iron

Port Size

3/4″ Male NPT Inlet/Outlet

Filtration Controller

Secondary Filtration

Spin-On Filter

Secondary Filter Elements

Construction

NEMA 4, Powder Coat or Optional NEMA 4X 304 Stainless Steel

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Alarm Features

Pump Shut-Down, High Vacuum, High Pressure, & Leak Detection

Weight

290 lbs +/- (131.5 kg)

Dimensions

(H x W x D)

36″ x 36″ x 12″

(91 x 91 x 30 cm)

* At 50 Hz, nominal flow rate decreases from 3 GPM to 2.4 GPM

Not for use with fluids that have a flash point below 100 deg. F.

STS 7004 Enclosed Automated Fuel Maintenance Systems

Not for use with fluids that have a flash point below 100 deg. F.

STS 7010 Enclosed Automated Fuel Maintenance Systems

Not for use with fluids that have a flash point below 100 deg. F.

STS 7020 Enclosed Automated Fuel Maintenance Systems

Not for use with fluids that have a flash point below 100 deg. F.

STS 7030 Enclosed Automated Fuel Maintenance Systems

Not for use with fluids that have a flash point below 100 deg. F.

STS 7040 Enclosed Automated Fuel Maintenance Systems

Not for use with fluids that have a flash point below 100 deg. F.

STS 7000 P35 Enclosed Auto<mated Fuel Maintenance Systems (For Use With In-Tank Fuel Pump)

Flow Rate

Up to 1,800 GPH (6,813.7 lph)

Serviceable Tank Size

25,000 to 50,000 gallons

(95,00 to 190,000 ltr)

Motor / Pump

Submersible Customer

Supplied up

to 35 GPM

Power

120V / 1 Ph / 60 Hz / 5A or 230V / 1 Ph / 50Hz 5A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Plumbing

Black Iron

Port Size

1 1/2″ NPT Inlet

1 1/2″ NPT Outlet

Filtration Controller

TSC 7000 Programmable Logic Controller with Touch Screen and Remote Monitoring, Modbus, TCP/IP, LAN and Internet Capability

Secondary Filtration

Dual Spin-on Filters

Secondary Filter Elements

Construction

NEMA 4 Powder Coated (or NEMA 4X Stainless Steel Optional)

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Alarm Features

Pump Shut-Down, High Vacuum, High Pressure, & Leak Detection

Weight

404 lbs +/- (183.3 kg)

Dimensions

(H x W x D)

56″ x 72″ x 17″

(142 x 183 x 43 cm)

Not for use with fluids that have a flash point below 100 deg. F.

Frequently Asked

Questions

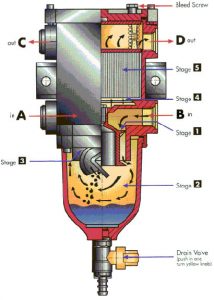

The following is the five stage fuel system of the typical Separ SWK-2000 Fuel Filter/Water Separator:

- Stage 1: From the inlet port, fuel flows through the interior vane system which imparts a circular motion to the fuel.

- Stage 2: Still in circular motion fuel reaches the bowl section where, due to this centrifugal motion water droplets and heavier particles are forced to the wall of the bowl eventually settling in the bottom of the bowl.

- Stage 3: In this stage the fuel has to pass the vane system positioned on the “outside” of the central housing. Due to differing length of the vanes and the twofold rapid change of fuel flow direction, smaller water droplets and finer particles will settle on the vanes. These settlements will agglomerate and when heavy enough fall to the bottom of the bowl. Already at this point the major portion of any contaminates in the fuel have been separated.

- Stage 4: Just below the filter element the flow area of the filter is increased significantly thus reducing the fuel flow rate. This calming effect allows even smaller water droplets and particulate to fall out settling on the inner surfaces of the housing forming larger droplets which eventually fall into the bottom of the bowl by gravity. Due to the before described pre-separation process the major portion of water and particulate present in the fuel will be in the bowl or on the inner surfaces of the filter thus greatly extending the filter element life.

- Stage 5: The final filtration of the remaining water and particulates still contained in the fuel will be effected by a replaceable filter element. These filter elements are produced from a special filter media and are available in different pore sizes. The clean fuel leaves the filter via one of the two outlet ports.

A Vacuum Gauge is provided on the top lid of the Separ Fuel Filter/Water Separator to allow for visual monitoring of Vacuum. When the Vacuum reading increases, indicating that the replaceable filter element has reached its capacity for holding particulate material, you know the filter needs changing. No more guessing or changing the filter too soon.

The fuel flow first enters the Fuel Conditioner immediately upon exiting the fuel pump. Operating on the principal of induction on the process of combining kinetic and magnetic energy to influence the behavior of electrons, the Fuel Conditioner provides a powerful magnetic field and the flow of fuel provides the kinetic energy.

As fuel deteriorates, clusters of fuel components break down and residue begins to accumulate, resulting in dark, hazy fuel with poor combustibility. This residue is composed primarily of asphalt components of the crude oil from which diesel fuel is refined that have fallen out of solution. The fuel becomes dark as the asphaltenes agglomerate and gain weight. The increase in size and mass of the fuel breakdown products lead to clogged filters and the build up of tank sludge.

As fuel deteriorates, clusters of fuel components break down and residue begins to accumulate, resulting in dark, hazy fuel with poor combustibility. This residue is composed primarily of asphalt components of the crude oil from which diesel fuel is refined that have fallen out of solution. The fuel becomes dark as the asphaltenes agglomerate and gain weight. The increase in size and mass of the fuel breakdown products lead to clogged filters and the build up of tank sludge.

Accumulation of water in the fuel tank provides habitat for bacterial and microbes brought into the tank through the breather vent or with fuel. As this microbial growth grows and reproduces, a bio-film accumulates and attaches to the tank walls and baffles of the fuel tank and may be seen floating in the fuel (and sometimes referred to mistakenly as “algae”).

This accumulation of bio-mass and fuel breakdown clogs filters, adversely impacts combustion efficiency, produces dark smoke from the exhaust, form acids that degrade injectors and fuel pumps, and adversely impacts performance. Eventually fouled diesel fuel will clog fuel lines and ruin your equipment.

The Fuel Conditioner dissolves the clusters, stabilizes the fuel, and eliminates tank sludge. The results are Clear & Bright Fuel, improved filterability, optimal combustion and clean fuel systems. It also adversely impacts the reproduction process of the microbes and prevents further growth (see the article “Why Bacteria Hate Magnets“, allowing continuing use of the fuel to eliminate the microbes. The process of how the Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling. As the Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the Fuel Conditioner. But you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. A spare parts kit for the Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

The Fuel Conditioner dissolves the clusters, stabilizes the fuel, and eliminates tank sludge. The results are Clear & Bright Fuel, improved filterability, optimal combustion and clean fuel systems. It also adversely impacts the reproduction process of the microbes and prevents further growth (see the article “Why Bacteria Hate Magnets“, allowing continuing use of the fuel to eliminate the microbes. The process of how the Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling. As the Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the Fuel Conditioner. But you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. A spare parts kit for the Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

The solution to suspected microbial growth and the results of asphaltene agglomeration in your fuel is the application of LG-X Series Fuel Conditioning Technology. Fuel Conditioners, when installed in-line in your equipment fuel system, will reverse the process of fuel breakdown, prevent microbial growth, restore fuel filterability, enhance combustibility, and prevent clogged filters and tank sludge. Optimizing fuel droplet size results in combustion efficiency, improved filterability and lower operating costs. (For a detailed explanation of how the LG-X Series Fuel Conditioner performs, see the web page “Learn More About Magnetic Fuel Conditioning”)

The LG-X Series Fuel Conditioner will also disperse and return to solution the asphaltene clusters the result in stored fuel degradation and return the fuel to a clear and bright appearance, a process sometimes referred to as “Fuel Polishing”. (For additional information, see “Diesel Fuel Polishing”)

Operating on the principle of induction on the process of combining kinetic and magnetic energy to influence the behavior of electrons, the LG-X Series Fuel Conditioner provides a powerful magnetic field and the flow of fuel provides the kinetic energy. The process of how the LG-X Series Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling.

As the LG-X Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the LG-X Series Fuel Conditioner. However, there are situations where the benefit of circulating your fuel through a magnetic unit has added benefit. Should the LG-X Series Fuel Conditioner be used in a situation where a fuel tank itself is in poor condition, where the tank may be rusted on the inside and rust flakes may be coming loose, the LG-X Series Fuel Conditioner would prevent the sharp metal flakes from progressing to the fuel filter where they may pierce the filter medium and allow unfiltered fuel to proceed to the fuel system. Also, should the source of your fuel be questionable, such as a marine vessel that fuels at island fuel stops with little oversight, or remote mining operations where a supplier may not be reliable, having the LG-X Series Fuel Conditioner installed to stop metal shavings or other ferrous debris that may be the result of maintenance on upstream distribution equipment could be a great benefit.

Should a fuel restriction that cannot be traced to a clogged filter element make the LG-X Series Fuel Conditioner suspect, you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. An extreme example is pictured to the left. A spare parts kit for the LG-X Series Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

To completely reverse the buildup of particulates and fuel components that have attached themselves to the fuel tank bottom and sides, the fuel system lines, and inside surfaces of engine components, combine the use of the LG-X Series Fuel Conditioner with regular use of AFC Series Fuel Catalyst and Tank Cleaning Additives. Unlike off-the-shelf additives that lubricate the fuel pump and limit their effectiveness to cleaning the injectors, the LG-X Series Fuel Catalyst and Tank Cleaning Additives reverse the long term buildup of sludge and degraded organic materials that have accumulated over time in the tank bottom, removes carbon buildup from engine components and stops the degradation of fuel injectors caused by the acids and degraded fuel components.

FP Series Centrifugal

Fuel / Water & Debris Separation

A centrifuge, when used as a filtration system, as with the FP Series of Fuel / Water Separators, is a piece of equipment that puts the fluid in rotation around a fixed axis (the center of the FP Series cylinder) and spins it in a circle applying a force perpendicular to the axis of spin (outward force) that can be very strong. The centrifuge works using the sedimentation principal where the centrifugal acceleration causes the denser substances and particles to move outward in the radial direction. In the case of the FP Series, the water is more dense than the diesel fuel and it is forced to the outside of the cylinder as the flow spins, and then the water drops down the sides of the cylinder to the bottom of the centrifuge. Particles, sludge, and debris all are also more dense than the diesel fuel, so they collect in the bottom of the cylinder with the water.

Because the removal of water, sludge and debris occurs due to the mechanical action of the fluid, there is no filtration media, such as with a bag filter or spin on filter elements that are consumed, making this type of water and particulate removal system attractive from a cost-of-operation standpoint. As this system, however, removes only “free” water (i.e.: water that is in the form of droplets) and does not remove water that is emulsified or absorbed into the water, and particulate removal is only effective at higher levels, perhaps 10 microns or larger, the FP Series System’s use is limited to that of a Primary Filtration unit and secondary or tertiary filtration for removal of fine particulates and emulsified water using water block filter elements is common.

In installations such as in the STS Series 6020 and 6040, the STS Series 7020 and 7040, a sensor is included near the bottom of the cylinder that connects to the System Controller to provide an alert that the FP Series Centrifuge has reached the point that drainage is required, and the system shuts down so that the water and other materials may be removed via a port and ball valve on the bottom of the cylinder.

The MTC Cart Mounted Systems utilize the FP Centrifuges, but as there is no controller on these systems, the need for draining the FP Centrifuge is determined by the sound of the MTC System’s Pump as it suctions fuel through the Centrifuge.

The MTC HC Pallet Mounted Mobile Tank Cleaning Systems all utilize the same FP Series Centrifuges as the primary filtration unit and has the same sensor and alerts as the above STS Series Systems.

All of the Fuel Polishing and Tank Cleaning Systems that are available on this web site, any one of which you may find meeting your fuel maintenance requirements, incorporates one or up-to four spin on fuel filter elements for the purpose of capturing and holding fine particulates or water (dissolved or emulsified).

The removal of water and fine particles to a level considered extreme in the past is now considered critically important, especially for today’s engines that utilize a High Pressure Common Rail Fuel Injection system that engine manufacturers have adopted. These engine manufactures now require filtration of all materials larger than 4 micron. Review the article “Diesel Fuel and Injector Failures” on this web site to understand why fuel cleanliness is more important now than ever before.

It is difficult to project how often these hard-working filters might need to be changed, and sometimes difficult to determine when they need to be changed during the fuel polishing process. Many of our systems incorporate Filtration and System Controllers that utilize pressure and/or vacuum sensors to determine when fuel flow through filter elements is being restricted necessitating the replacement of these filters.

It is difficult to project how often these hard-working filters might need to be changed, and sometimes difficult to determine when they need to be changed during the fuel polishing process. Many of our systems incorporate Filtration and System Controllers that utilize pressure and/or vacuum sensors to determine when fuel flow through filter elements is being restricted necessitating the replacement of these filters.

Other systems, such as the TK Series or MTC Series Cart Mounted systems do not have automated controllers, but in each case we do utilize pressure gauges that will tell you when the flow of fuel through the filter element is restricted, increasing the back-pressure in the fuel flow and alerting that the filter is “used up”.

It is very typical that the first few times that a re-circulation tank cleaning is undertaken on a tank that has been in service for many years, without any prior cleaning being performed, that several filters are quickly used up in cleaning the tank. But after these several intense cleanings, the filters should last much longer, but only experience and maintaining a log of the fuel flow that has been passed through a set of filters, and how many times a tank has been cleaned will you begin to determine going forward how many filters you are likely to consume and how many filters should be kept on hand.

It is very typical that the first few times that a re-circulation tank cleaning is undertaken on a tank that has been in service for many years, without any prior cleaning being performed, that several filters are quickly used up in cleaning the tank. But after these several intense cleanings, the filters should last much longer, but only experience and maintaining a log of the fuel flow that has been passed through a set of filters, and how many times a tank has been cleaned will you begin to determine going forward how many filters you are likely to consume and how many filters should be kept on hand.

Many commercial tank cleaning companies that often tackle the cleaning of tanks that have never been cleaned before will regularly go through many filters. In these situations, using systems, such as the MTC Series Cart Mounted and HC Pallet Mounted systems that use mechanical centrifugal primary filtration prior to directing fuel flow through the more expensive spin on filters saves considerable money.

PF-10 and PF-30 HD

Bag Filter Vessels

Also, when you know that many tanks you will tackle are bad, using the PF Series Pre-filter Bag Units can give you a great deal of savings. The PF Series Bag Units can be used without bags initially to remove water and “the big pieces”, and then incorporate large micron bags (as high as 800 microns) in the early phases of the tank cleaning process, and work your way down to 5 micron bags before using the more expensive but much more efficient spin-on filters. The bags may be dumped out, flushed and re-used for a limited number of times, and replacement bags are quite inexpensive.

It is critically important to re-circulate the fuel through the Fuel Polishing and Maintenance System that best suits your requirements, whether it is a hand held TK Series System, an MTC Series Mobile System, an FPS Series Compact System, or an STS Advanced Automated Enclosed Fuel Maintenance System. But the re-circulation process does not create sufficient fuel flow and agitation in the tank, in many instances, to really knock the slime and sludge off the sides and inside top of the tank, and not enough force to loosen the sludge that has been accumulating on the floor of your fuel tank for years!

What you need is something to clean the tank and put this bio-film and slime into the fuel flow so that the Fuel Polishing and Maintenance System can filter out the debris and the Fuel Conditioner can get to the microbes and break apart the agglomerated asphaltene component of the fuel.

Moving the suction hose stinger (an extension to the hose, usually rigid, allowing for the control of the suction line intake end) of the Fuel Polishing System around the bottom during the fuel re-circulation phase does stir up considerable material for the suction line to deliver to the Fuel Polishing System, but there needs to be something that can dissolve the slime and organic material off the tank walls, top, and floor prior to the re-circulation process that will also keep working between Fuel Polishing Treatments.

It is recommended that the diesel fuel tank be treated with the AFC Series Broad Spectrum Additive Concentrate appropriate to your application a day or two prior to the first re-circulation. It should be added to a full tank of fuel or the tank filled just after the additive is introduced to the tank.

After completing the initial fuel polishing re-circulation, continue the use of AFC Series Additives at least once or twice every six months thereafter to assure the fuel tank remains clean and the fuel is stabilized. This will enhance and accelerate the long term tank cleaning process, mainly the hardened sludge in the tank bottom, by breaking down and dissolving the existing tank sludge.

Check the Tank Bottom for Water at Regular Intervals

Always check the fuel tank for an accumulation of water in the bottom of the tank prior to doing a re-circulation. Using a rod, sometimes used to measure fuel in a storage tank, or a length of PVC pipe, spread a line of Kolor Kut Water Finding Paste on the side of the rod or pipe and insert to the bottom of the tank. If the paste touches water, it will change colors, showing how much water is in the tank requiring removal.

Treating a full tank of fuel is important as you don’t want to clean just the bottom half of the tank. You want the additive treated fuel to touch every part of the sides and, if possible, the top of the tank — anywhere the fuel touches during equipment operation.

The AFC Series Fuel Additives are industrial strength and concentrated for the focused dual-purpose of:

- First – working hand-in-hand with the Fuel Conditioning and Tank Cleaning Systems cleaning fuel tanks in preparation for periodic circulation and treatment of the fuel; and

- Second – as a continuing part of a Fuel Management Plan to maintain the cleanliness of storage tanks and fuel systems and assuring that your fuel maintains Optimal Fuel Quality, that we define as fuel that is like it was when it left the refinery, for as long as you depend on the fuel to efficiently operate your equipment.

Removal of Residual Water

Prior to the initial and any subsequent fuel polishing re-circulation, pump any measurable accumulated water out of the tank for proper disposal. It is, however, often impossible to remove all of the water. The AFC-705 Catalyst and Tank Cleaning Additive contains a surfactant that will emulsify this residual water up into the fuel for removal by a Water Block Filter on the Fuel Polishing System.

The AFC-710 Catalyst and Tank Cleaning Additive, which is Tier 4 Compliant, does not include the surfactant component, but otherwise works the same as the AFC-705 to dissolve deposits and stabilize the fuel. As and option to the liquid AFC-710, a powdered form of AFC-710 is also available. It is easier in certain instances to handle, store and transport.

Additive Dosage

Depending on the condition of the fuel and the amount of sludge build-up, it is recommended to initially use a double dose of one to twenty-five hundred (1:2500 – one oz. to 20 gallons of fuel) and circulate the capacity of the tank five times. The use of AFC Fuel Catalyst has proven to be essential in accelerating the tank cleaning process. AFC-705 and 710 contains detergent, dispersant, corrosion inhibitor, lubricity enhancer and combustion catalyst. AFC Additives do not contain biocides.

For engines manufactured in 2007 and later, use AFC-710, available in both liquid and powdered form. AFC-710 does not contain the surfactant (used to emulsify residual water into the fuel for removal in the circulation process as does AFC-705), a component that does not allow for qualification as a Tier 4 product.

Tank Cleaning & Fuel Treatment for Cold Weather Use

For cold weather operations, AFC Fuel Catalyst AFC-805 is a unique and powerful anti-gelling broad-spectrum fuel additive specifically formulated for use in Diesel, Bio-fuels, Gasoline, Kerosene, and HFO. AFC-805 can be used as part of any preventative fuel maintenance program, and is ideal for use in bulk storage fuel tanks in cold weather environments. AFC-805 enhances the breakdown and removal of sludge, slime, and bio-fouling from tank walls and baffles that are difficult to access. It continues to work in storage tanks cleaning and stabilizing fuel for up to 12 months with a single dose.

It is not unusual that a Fuel Polishing and Tank Cleaning System is installed at a level above the fuel that is to be maintained, especially in underground tanks or base (or “belly”) tanks of generators. How do you maintain the prime on the pump in such an installation?

Foot Valves are handy little devices that can be installed at the end of a pipe line in a suction lift application. They function as a check valve to maintain the prime and also have a strainer affixed to the open end. The check valve is spring assisted. When the pump is turned on, the suction opens the valve and the fluid flows. When the pump stops, the valve responds again by closing. This stops fluid from draining out of the pump column and causing the pump to lose prime every time it turns off.

Foot Valves are handy little devices that can be installed at the end of a pipe line in a suction lift application. They function as a check valve to maintain the prime and also have a strainer affixed to the open end. The check valve is spring assisted. When the pump is turned on, the suction opens the valve and the fluid flows. When the pump stops, the valve responds again by closing. This stops fluid from draining out of the pump column and causing the pump to lose prime every time it turns off.

The strainer also keeps debris from becoming lodged in the foot valve. This would result in the valve being stuck in the open position, and all the fluid draining from the pump column. That nullifies the point of the foot valve! Some foot valves offer tight mesh, others offer a wider grid strainer.

Any installation of a Fuel Maintenance System dedicated to the cleaning and conditioning of fuel in one or multiple tanks would benefit from the inclusion of a foot valve. The efficiency of a system that is programmed to operate on a periodic basis would suffer if an operator must prime the pump each time a tank is due for maintenance.

The Multi-Port Flowpath Actuated Valve System is available to operate in unison with several of the FPS Fuel Polishing Systems. Each MP-VS Valve Set includes two (2) Solenoid Valves (one for the suction and one for the discharge line) and one Foot Vale to be installed on the end of the suction pipe. One valve set is typically installed in each partitioned section of the base tank.

STS 7000 Series Programmable Functionality

STS 7000 Series Fuel Cleaning, Conditioning and Tank Cleaning Systems feature advanced programmability, are fully automated, stand-alone Fuel Maintenance Systems that remove and prevent the buildup of water, sludge and contaminants in tanks while eliminating and preventing microbial contamination wherever fuel is stored or used. Adding an STS 7000 Series System that meets your requirements and needs will optimize your fuel and remove particulate, separate water, and condition your diesel fuel and bio-fuels. To understand the critical importance of having a Fuel Management Plan that includes an STS Series Fuel Management System, review the article on this web site that explains that Most Diesel Engine Failures Originate in the Fuel Tank (the Real Story of Bad Diesel Fuel).

The STS 7000 Series Fuel Cleaning Systems are specifically designed for permanent installations indoors or outdoors and are self contained within a lockable NEMA standard enclosure. The STS 7000 Series Systems keep your tanks clean and your fuel in “Clear & Bright” pristine condition at all times providing maximum efficiency and minimal emissions. The patented unique LG-X Series Fuel Conditioner, included on every STS System, reverses fuel deterioration and removes sedimentation to sub micron levels, preventing clogged filters, extending injection system service life, and reducing smoke, emissions and downtime.

All STS Series 7000 Fuel Conditioning & Tank Cleaning Systems feature:

- Filtration Controllers

- Fully Automated & Programmable Operation

- Integration with Facility Monitoring Systems

- Modular “Plug & Play” Flexibility

- Unique Safety and Alarm Features

- Continuous-Duty Pumps, Viton Seals

- Leak Detection with Emergency Shut-Down

The STS 7000 Series Fuel Polishing Systems are designed with a range of safety features that allows for remote and unattended operation. The Touch Screen Programmable Logic Controller features the following:

- Establish a fuel polishing runtime schedule with up to three start and stop times for each day of the week

- Available system integration with external monitoring systems for observation of system statuses

- Automatic Alerts

- Pump Shut Down when Filters Require Service

- Pump Shut Down when a Leak is Detected Inside Enclosure

- Alert when High Water is Detected in Fuel Filter/Water Separator Bowl

- Pump Shut Down when Filters Require Service

- Pump Shut Down when a Leak is Detected Inside Enclosure

- Alert when High Water is Detected in Fuel Filter/Water Separator Bowl

- Pump Shut Down when High Vacuum is Detected

- Pump Shut Down when High Pump Pressure is Detected (secondary filters require change)

- Pump Shut Down when Low Fuel flow is Detected

- Controller Memory Backup to Retain Program during Power Outages

- External Remote Shutdown Feature

- Emergency Stop Outside Enclosure

Each STS 7000 Series Fuel Cleaning System features an HMI Programmable Logic Controller (PLC) with Touch Screen Controller, Mobus, TCP/IP, LAN, and internet connectivity, with alerts by email or SMS. The Controller periodically processes your stored fuel according to the schedule appropriate for your operation. Safety features assure efficient, safe and environmental stewardship in all operations.

Fuel Management Plan

An STS Series Fuel Management System is the central component of a Fuel Management Plan. Establishing a fuel management and maintenance protocol must include periodic monitoring and removal of accumulated water from the tank, periodic treatment with AFC Series Fuel Catalyst, Fuel Stabilizing, and Tank Cleaning Additive for tank cleaning, residual water removal, particulate filtration, microbe neutralization, and polishing of the fuel, returning the fuel to its clear and bright appearance, and to a state of optimal performance.

Selecting the STS 7000 Automated Fuel Polishing System System that is Right for You

Each Fuel Management System operates utilizing the same general functionality, but they vary principally in pump capacity, filtering capability and power requirements to better suite the needs of the individual facility requiring a dedicated fuel maintenance system. Generally we recommend that a system be sized to achieve the circulation of three times the fuel tank capacity in 75 hours of operation. There are five (5) systems in the STS 7000 Series, with one having the right capabilities to match your needs:

- STS-7003 – 180 GPH – Tank Range: 500 to 4,000 gallons

- STS-7004 – 240 GPH – Tank Range: 3,000 to 6,000 gallons

- STS-7010 – 600 GPH – Tank Range: 6,000 to 15,000 gallons

- STS-7020 – 1,200 GPH – Tank Range: 10,000 to 30,000 gallons

- STS-7030 – 1,800 GPH – Tank Range 15,000 to 45,000 gallons

- STS-7040 – 2,400 GPH – Tank Range 20,000 to 60,000 gallons

- STS-7000 P-35 – 2,100 GPH – Tank Range 25,000 to 50,000 Gallons

Note that the STS-7000 P35 utilizes a customer supplied in-tank pump and is capable at operating up to 30 GPM.

A detailed table of the capabilities, component description, power requirements and other information for each STS 7000 Series Automated Fuel Polishing System is available in the drop down box on the left side of this page.

Each STS-7000 Series System features a Programmable Logic Controller (PLC) to periodically process your stored fuel according to the schedule appropriate for your operation. Safety features assure efficient, safe and environmental stewardship in all operations.

Applications

A fuel storage tank that is used to support multiple generators at a data center, office building, remote island or wilderness resort, secure government facility or military base operations are likely to have a need for the periodic conditioning and tank cleaning of a large fuel storage tank. Major institutional facilities, such as hospitals or universities, may have centralized emergency power generating that provides for the backup power to be distributed over many floors of a high rise building or to several buildings.

Fuel Conditioner

LG-X Series

Fuel Conditioner

Critical to the Fuel Polishing process is the Fuel Conditioner. Without this component, all you accomplish is the filtering of your fuel. The Real Story of Bad Diesel Fuel is that there are two main causes of Fuel Problems:

- Micro-organisms, bacteria and enzyme activity, fungus, yeast and mold get into your fuel that cause diesel fuel degradation and the formation of waste products that can be visible floating around in your fuel tank (commonly, but erroneously, referred to as “algae”).

- Diesel Fuel begins to degrade with age as soon as it leaves the refinery. The asphaltene component of diesel fuel (the heaviest asphalt portion of the crude oil) that is in suspension in the fuel when it leaves the refinery, but begins agglomerating and leads to larger and larger clusters and solids, which are very difficult to completely combust (causing exhaust smoke). As these solids grow, they will not pass through the filter element and result in filter plugging after a very short period of time.

The Fuel Conditioner not only prevents both problems, it will prevent the microbial contamination from growing, and will reverse the breakdown of the heavy constituents of diesel fuel that cause the fuel to become dark or black, restoring the fuel to the clear, bright condition it had when it left the refinery and return the fuel to the state of optimal quality, hence the term “Fuel Polishing”. For a complete understanding of the importance of the Fuel Conditioner in your fuel maintenance program, read the “Diesel Fuel Polishing” article on this website.

Fuel Polishing Controllers

Two different Fuel Polishing Controllers are offered with the STS 7000 Series Automated Enclosed Fuel Maintenance Systems, matched to the capabilities of the Systems.

TSC-70 Fuel Polishing Controller

Four STS 7000 Series Systems utilize the TSC-70 Automated Fuel Polishing Controller as their Standard Controller:

- STS 7003 – 180 GPH

- STS 7004 – 140 GPH

- STS 7010 – 600 GPH

- STS 7020 – 1,200 GPH

The TSC-70 features the following capabilities (Note inclusion of multiple options may require upgrade to the TSC-80 Controller):

- User Interface:LCD/ Touchscreen

- Runtime Scheduling

- System Alerts/Alarms

- External Integration: Modbus TCP/IP & Summary Dry Contacts

- Power Options: 120V/60Hz/1Ph, 208-230V/60Hz/1Ph, and 230V/50Hz/1Ph

- Dimensions: 14″ x 12″ x 6″

- Multi-Tank Polishing/Transfer (up to 4 Tanks)

- Vacuum/Pressure Switches

- Automatic Water Drain (AWD) (Optional)

- Vacuum/Pressure Transducers (Optional)

- Flow Switch

- Flow Transmitter (Optional)

- Remote Drop-in (Optional)

- Multi-Point Flow Path – 2 to 8 pairs (Optional)

TSC-80 Advanced Automated Fuel Polishing Controller

Three STS 7000 Series Systems utilize the TSC-80 Automated Fuel Polishing Controllers as their Standard Controller. The TSC-80 provides these larger Tank Maintenance Systems with heavy duty power capabilities and other expanded functionality. The TSC-80 is Standard on the following STS 7000 Series Systems:

- STS 7030 – 1,800 GPh

- STS 7040 – 2,400 GPH

- STS 7000 P-35 – 2,100 GPH

The TSC-80 features the following capabilities in addition to those offered on the TSC-70 controller:

- Power Options: 208-230V/60Hz/1Ph, 240V/60Hz/3Ph, and 480V/60Hz/3Ph

- Dimensions: 16″ x 14″ x 8″Flow Control (P-35 Only)

- Flow Control (P-35 only)

Enclosure Cabinet Options

All STS 7000 Series Systems are standard with a NEMA 4 (IP66), 13 (IP65), 4X (IP 66), and 12 (IP55) rated enclosure for indoor and outdoor installations constructed with 14-gauge steel with continuously welded seams, concealed hinges and finished in polyester powder coat inside and out over phosphatized surfaces. A spill basin is included with leak detection monitored by the System Controller. The enclosure has louvered side panels, brackets for wall mounting components and a literature pocket. Additional color options available.

An optional 304 Stainless Steel Enclosure is also available. Choose the Enclosure option to upgrade your purchase to a Stainless Steel Enclosure on the Shopping Cart page.

The Enclosure Heater (listed under STS Series Fuel Maintenance Options) is an option used to maintain a certain temperature within the system enclosure and ensures that components in contact with water do not freeze. It also ensures that electronics stay within their operating range. The Enclosure Heater comes with a built-in thermostat, and can run continuously in cold environments.

Optional Automatic Water Drain System

Auto Water Drain

Option in STS 7003 System

Showing Both Manual Drain &

AWD Pump & Screen

All STS 7000 Series Fuel Maintenance Systems may be purchased with the Optional Automatic Water Drain (AWD) System. The AWD is controlled by the System Controller (PLC), a WATECT 550 Water Sensor, water strainer, and a 15 gallon reservoir barrel to catch and hold water expelled from the bowl of the primary filter. The barrel includes an overflow protection switch to over-ride the drain process if the barrel is full. A floor stand is available to support the barrel separately and a 200 watt strap heater is available separately to wrap around the barrel to help prevent the contents from freezing. You may order the AWD when placing your order on the Shopping Cart page.

Multiple Tank Capability

All of the STS 7000 Series Fuel Maintenance Systems have the capability to a Multi-Tank Option to service multiple (up to 4) closely located fuel tanks. The multi-tank option is designed to allow for multiple fuel tanks to tie into a single fuel polishing unit. By integrating actuators that control the sorce of fuel being fed into, out of, or through the unit, controlled by an automated customer selected control sequence. The multi-tank option can ensure optimal fuel quality for up to four fuel tanks, depending on the STS System installed at the location.

The system has an in-built feature to transfer fuel from one tank to another via the manual operation mode. Additional hardware is required to sense overfilled fluid levels.

- STS 7003 – Two (2) Tank Servicing

- STS 7004 – Two (2) Tank Servicing

- STS 7010 – Up to Four (4) Tank Servicing

- STS 7020 – Up to Four (4) Tank Servicing

- STS 7030 – Up to Four (4) Tank Servicing

- STS 7040 – Up to Four (4) Tank Servicing

The Multi-Tank Option (Part #: STS 70XX Opt-2T) is the basic package that consists of the 2-Tank Actuated Ball Valve System with upgrades to the Programable Logic Controller (PLC). For more than two tanks, the otional STS 70XX-ADD T part is required for each additional tank which consists of the additional Actualted Ball Valves required to control flow for one tank.

For fuel systems requiring the maintenance of more than four fuel tanks, a custom engineered solution is available. Contact us should you have any questions.

Additional Options

The following are additional options available on STS 7000 Fuel Polishing Systems:

- Manual Additive Injection – Manually draw additive into the polisher with a dedicated supply port and ball valve – Available on the STS 7003, STS 7004, and STS 7010 (Automatic Additive Injection is available as a custom option on the STS 7020, STS 7030, STS 7040, and STS 7000 P-35)

- Vacuum / Pressure Transducers – Replace standard pressure switch for detailed monitoring of pressure levels in the system.

- Flow Transmitter – Replace standard flow switch for detailed monitoring of flow rate in the system

- Fuel Heater – Warm up circulated fuel to resist gelling in freezing temperatures

- Enclosure Heater – Prevent the build up of condensation inside the system enclosure due to temperature changes

Note some options require a Controller upgrade from the TSC-70 Controller to the TSC-80 Controller.

AFC Series Fuel & Tank Cleaning Additives

Critical to maintaining fuel in its optimal quality and the management of fuel tanks and engine injector components is the use of an additive treatment program.

The AFC Fuel Catalyst family of additives are formulated for use in diesel, gasoline, bio-fuels, kerosene and Heavy Fuel Oil (also known as heavy fuel oil or residential fuel oil).

AFC Fuel Catalyst is not like other additives readily available at truck stops, auto and truck parts retailers, marine supply stores, or sold by numerous on-line suppliers. AFC is formulated and blended for the focused dual-purpose of:

AFC Family of

Diesel Fuel Additives

First – working hand-in-hand with the LG-X Series Fuel Conditioners, and the STS 6000 Series Fuel Polishing and Tank Cleaning Systems cleaning fuel tanks in preparation for periodic circulation and treatment of the fuel; and

Second – as a continuing part of a Fuel Management Plan to maintain the cleanliness of storage tanks and fuel systems and assuring that your fuel maintains Optimal Fuel Quality, that we define as fuel that is like it was when it left the refinery, for as long as you depend on the fuel to efficiently operate your equipment.

Optional Features

- Manual Additive Injection – Manually draw additive into the Fuel Polisher with a dedicated supply port and ball valve. Also see the Tank Cleaning Additives below

- Auto Water Drain (AWD) – Automatically drain water separator of collected water for decreased frequency of maintenance. Includes water collection tank and Controller control when tank reaches capacity.

- Flow Transmitter – Replace standard flow switch for detailed monitoring of flow rate in the system

- Multi-Tank Polishing/Transfer – Polish and transfer fuel between multiple fuel storage tanks (up to 2-tanks, 4-tanks with TSC-70 Controller upgrade)

- Multi-Port Flow Path – Add multiple supply and return valves for better tank cleaning coverage (Requires upgrade to TSC-70 Controller)

- Fuel Heater – Warm up circulated fuel to resist gelling in freezing temperatures

Upgrade to the TSC-80 Advanced Automated System Controller may be required for certain option combinations.

Additional Optional Features

- Power Converter – for 12 / 24 Volt systems to operate from 110-Volt to 230-Volt power.

- Alarm Strobe: provides flashing light signal that System shut down and maintenance service is required.

- Audible Alarm: provides audible signal that System shut down and maintenance service is required

- Digital Flow Meters: provides digital readout of volume of fuel treated.

- Replacement Filters: for your FPS Series Fuel Polishing System. Also see the “Additional Information” section below for Replacement Fuel Filters for the various FPS Series Systems.

- Cabinet Heater: protects System components and allow for operations in cold climates – available in 100 Watt (single wide cabinet) and 400 Watt (double wide cabinet)

- Extended System Warranty – Maximum 4 years (contact us for details).

An Ounce of Prevention is Worth a Pound of Cure

The following are products that are available on the diesel-fuels.com website that will help you in preventing debris, microbes and moisture from entering your fuel tank, and removing them early before they may cause problems. Also, other products to help with fuel and fuel tank maintenance:

- AFC Series Fuel Additives for fuel conditioning, stabilization, tank cleaning, and combustion catalyst. Also see the “Additional Information” section below for information on Tank Cleaning Additives.

- Breather Vent Filters with desiccant material that will stop debris and moisture from entering your fuel tank through the vent breather.

- WE-12 Water Eliminators capture and hold water from condensation that may accumulate in your fuel tank.

- Diesel Recovery quickly dissolves gelled fuel caused by cold temperatures and thaws frozen fuel lines and filters.

- Access Plates for creating a removable access port in fuel tanks to accommodate inspections and tank maintenance.

- Fuel Sampling Devices ease the recovering of fuel for testing from your fuel storage tank. TS Series Samplers are dropped into the tank and capture a sample from different depths. A hand pump is also available for obtaining samples. Sample bottles are also available for use with both options.

- Fuel Testing Kits provide an early warnings of the presence of contamination in your fuel.

Additional Information

Primary Filters:

Separ Filters for SWK 2000/10 – STS 7003

Separ Filters for SWK 2000/18 – STS 7004

Separ Filters for SWK 2000/40 – STS 7010

Racor Filters for the FBO-14 – STS 7030

Secondary Filters:

Spin-on Filters – STS 7003, STS 7004, STS 7010, STS 7020, STS7040

Racor Filters for the FBO-14 – STS 7030

STS 7003:

STS 7004:

STS 7010:

STS 7020:

STS 7030:

STS 7040:

STS 7000 P-35:

STS 7000 Series Enclosed Programmable Fuel Maintenance Systems

The online shopping cart can calculate shipping charges on orders that have a combined Shipping Weight of under 150 pounds. As all STS 7000 Fuel Maintenance Systems exceed this weight, orders for these systems must be handled manually. Contact us for additional information, a full quote for a system to meet your requirements, or to place an order for an STS 7000 Series Fuel Maintenance System.