FV Series

High Volume Filtration Housings

FV Series High Volume

Filtration Specifications

Model

FV-120 *

Maximum Flow

120 GPM (450 LPM)

Maximum Working Pressure

150 PSI

Ports

2″ NPT Inlet / Outlet (“F” Model with 2″ Flanges)

Exterior / Interior Finish

Epoxy Coating

Lid

3 Bold Swing Down Lid

Housing Construction

Carbon Steel

Overall Size

31 5/8″ H x 12 1/8″ W

Inlet to Outlet Dimensions

12″ for 2 ” NPT (13.5″ for flanged model)

Pressure Gauge Port

1/4″ Port for Optional Differential Pressure Gauge Kit

Required Filter Elements

1 – 6″ x 18″ Element

Empty Operating Weight

111 lbs (50.3 kg)

* Flanged Units for FV-120 Available by Special Order

Not For Aviation Use

Model

FV-150 *

Maximum Flow

150 GPM (567.8 LPM)

Maximum Working Pressure

150 PSI

Ports

2″ NPT Inlet / Outlet (“F” Model with 2″ Flanges)

Exterior / Interior Finish

Epoxy Coating

Lid

3 Bold Swing Down Lid

Housing Construction

Carbon Steel

Overall Size

50 1/2″ H x 12 1/8″ W

Inlet to Outlet Dimensions

12″ for 2 ” NPT (13.5″ for flanged model)

Pressure Gauge Port

1/4″ Port for Optional Differential Pressure Gauge Kit

Required Filter Elements

2 – 6″ x 18″ Element

Empty Operating Weight

140 lbs (63.5 kg)

* Flanged Units for FV-150 Available by Special Order

Not For Aviation Use

Model

FV-300

Maximum Flow

300 GPM (1135.6 LPM)

Maximum Working Pressure

150 PSI

Ports

3″ Flanged Inlet / Outlet

Exterior / Interior Finish

Epoxy Coating

Lid

8 Bold Swing Away Lid

Housing Construction

Carbon Steel

Overall Size

59 1/4″ H x 24″ W

Inlet to Outlet Dimensions

24″ for 3″ Flanged

Pressure Gauge Port

1/4″ Port for Optional Differential Pressure Gauge Kit

Required Filter Elements

4 – 6″ x 18″ Element

Empty Operating Weight

600 lbs (50.3 kg)

Not For Aviation Use

Model

FV-500

Maximum Flow

500 GPM (1892.7 LPM)

Maximum Working Pressure

150 PSI

Ports

4″ Flanged Inlet / Outlet

Exterior / Interior Finish

Epoxy Coating

Lid

8 Bold Swing Away Lid

Housing Construction

Carbon Steel

Overall Size

78 3/8″ H x 28″ W

Inlet to Outlet Dimensions

28″ for 4 ” Flanged

Pressure Gauge Port

1/4″ Port for Optional Differential Pressure Gauge Kit

Required Filter Elements

8 – 6″ x 18″ Element

Empty Operating Weight

775 lbs (351.5 kg)

Not For Aviation Use

FV Series High Volume

Filtration Differential

Pressure Gauge Kit

Specifications

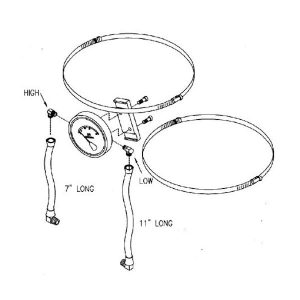

The Differential Pressure Gauge Kit Part #90601 is designed for use on the FV-120, FV-150, and FV-300 High Volume Filtration Vessel. The following shows the installed Kit and a view of the components:

The Differential Pressure Gauge Kit Part #90602 is designed for use on the FV-500 High Volume Filtration Vessel. The following shows the installed Kit and a view of the components:

Providing High Volume Filtration Capacity with Flexible Capacity

Fuel is the lifeblood of your system. You can have the best back up power generation system or the best equipment in your fleet, but if the fuel is contaminated, is high in particulates or has water emulsified into the fuel that presents a hazy appearance, you have problems. The FV Series of High Volume Filtration vessels provide fast filtration for distributor loading racks, or receiving operations.

You place an order for fuel, but you never really know where it comes from, where its been or how long it was in storage. Had the source storage tank, only 1/3 full, sat idle for the past six months? Did the tanker truck that delivered it get pulled out of the back lot at the last minute to substitute for a truck with a bad wheel bearing? Is the fuel you’re getting what you expect?

You know that if the fuel is in peak condition the equipment runs better. There is no smoke, the engine components last longer, fuel filters last longer, the engines(s) run more efficiently and you”re boss is happy. You know you need to keep the fuel in top condition, especially in the down season.

But a plan of Best Practices must include prevention. The solution is to filter each load of fuel when it is taken on.

Downstream Tank Maintenance

This typically is a transfer of fuel from your distributor to your main fuel storage tank. High Volume Filtration of the fuel as it goes into the storage tank is critical. But assume a construction company has equipment at a large construction site, and each piece of equipment gets fueled daily. Or maybe this is an office or industrial complex, or a municipal water or sewage treatment facility where there are Emergency Power Generators spread out in numerous buildings, including data centers.

The fuel in the main storage tank should be treated with AFC Series Diesel Fuel Catalyst, Stabilizer and Tank Cleaning Additive (and in cold weather, with an anti-gel additive such as AFC 805).

The high volume filtration of fuel in the transfer from your main fuel storage tank to your fuel truck should be Conditioned, and the fuel from the fuel truck to the equipment should be filtered and Conditioned. For the high volume filtration fuel transfers, there is an FV Series High Volume Filter Housing to fit your requirements for filtering water and particulates from the fuel before it goes into your tank and before it further goes into the fuel truck.

Adding supplemental filtration and the inline LG-X Fuel Conditioner and the AFC Series Fuel Additive as fuel flows from the upstream storage tank to each piece of equipment assures that every piece of equipment has clean, stabilized fuel and a clean fuel tank.

Quarantine Tanks

Tanks that are dedicated to receiving incoming fuel is becoming more popular. This arrangement provides the opportunity to filter and Condition the fuel before it is mixed in with the fuel that is known to already be in optimal condition due to previous fuel treatments. Mixing newly taken on fuel with existing fuel requires re-treatment of all the fuel. When the fuel in the quarantine tank is filtered, Conditioned and AFC Additive is introduced, then this new fuel is transferred from the quarantine tank to the main storage tank(s), later to be moved from the storage tanks into the equipment tank or day tank.

Distributor High Volume Filtration

The FV Series High Volume Filtration is ideal for fueling racks and bulk fluid transfer during high volume dispensing. It removes common contaminants from gasoline, ethanol blends up to E15, diesel fuel, biodiesel blends up to B100, fuel oil, ultra-low sulfur diesel (ULSD), fuel oils, lubrication oils, hydraulic oils, synthetic oils, and many solvents and thinners.

- Available in configurations up to 500 gpm / 1892.7 lpm maximum flow.

- 150 psi rating

- Epoxy coating inside and out

- Carbon steel housing

- Gauge ports standard

- #90601 Optional Differential Pressure Gauge Kit Available for FV120, 150, 300 (Select Option When Choosing FV Unit)

- #90602 Optional Differential Pressure Gauge Kit Available for FV-500 (Select Option When Choosing FV Unit)

- Removes common contaminants such as dirt, dust and rust

- Provides Increased filtering capacity

- Easy opening and access with swing lid

- Multiple FV units can be configured in parallel for increased flow rates, or in series for customized filtration

Power Generation

You can’t afford to allow that one tanker load of fuel to contaminate the whole 10,000 gallon tank of fuel you need … it”s too late to plan ahead when the lights go out.

Sure, you have a plan. Part of every plan of Best Practices is to be prepared. If the fuel is bad, you can always run it through the boiler and get a fresh tank, but the cleaning of the tank the last time that was necessary was really expensive.

Marine Vessels

Or you’re responsible for a really nice yacht. But you take on fuel from some really marginal sources. Some of the places you travel to are really nice on the outside, but just don’t have the infrastructure and quality control to give you confidence in the product. And just taking on water (no extra charge!) reduces your fuel storage capacity and you know it will lead to problems down the road.

Best Practices

Assuring that fuel you accept is as clean and free of water, whether free water droplets or emulsified water (hazy fuel) needs to be paramount. High volume filtration and incorporating water block / coalescing filtration media to incoming fuel assures that fuel is basically clean. The FV Series of High Volume Filtration Vessels will give you that assurance.

Once in your tank, circulating the fuel with an STS Automated Fuel Maintenance System assures the fuel is clear and bright, free of water and contaminants, and will be ready when the need arises.

Additional Information

![]() FV-Series-High Flow Filter Specification Sheet (General)

FV-Series-High Flow Filter Specification Sheet (General)

![]() FV-300 (Viking 3F) and FV-500 (Viking 4F) Specification Sheet

FV-300 (Viking 3F) and FV-500 (Viking 4F) Specification Sheet

Filter Elements:

- FV-120 – 1 Element

- FV-150 – 2 Elements

- FV-300 – 4 Elements

- FV-500 – 8 Elements

FV-Series Shopping Cart

JPM Series Filter

Elements Shopping Cart

-

Filter Elements - JPM Series (6)

JPM Filtration Cartridges JPM Filters are the Preferred Filter Elements for use in the FV Series High Volume Filtration Housing: • Cellulose Particulate Filters in 2, 10, and 30 Micron Rating • Cellulose Particulate & Water Block Filters in 2, 10, and 30 Micron Rating • High Performance Microglass Filter Elements in 3, 7, and 10 Micron Rating FV Series…