Desiccant Fuel Tank Breathers by Des-Case

All diesel fuel storage and equipment tanks draw air into the tank as fuel is pumped out of the tank or consumed by the engine or engines that depend on the fuel for providing the source of its power. If you have a 50 gallon tank, a 1,000 gallon tank, or a 50,000 gallon tank, the fuel being pulled out is displaced by air drawn in through a vent. Without this mechanism, the tank could collapse.

What We’ve Learned…

- A well executed reliability program extends the life of industrial lubricants and reduces your environmental footprint

- Maintaining clean oil can extend equipment life as much as as 2 to 5 times

- It can cost ten times as much to remove contamination from equipment than it does to exclude it

- Moisture contamination is the second most destructive contaminant in most systems

In addition, above ground tanks generally present another problem. Although underground tanks maintain a steady temperature, minimizing expansion and contraction due to temperature changes, they also present expensive challenges in monitoring for fuel leaks and performing inspections of the tank to insure tank integrity. For this reason, many operations have opted to adopt above ground tanks. However, during any given day temperature changes cause expansion and contraction of the tank itself, as well as the fuel inside the tank. This causes the air to be expelled during the day, and then new air to be drawn into the tank as temperatures cool over night, even when no fuel is being withdrawn or consumed.

But the air being pulled into the tank in both situations is not clean. It contains moisture that condenses on the tank walls. This water forms droplets and migrates to the tank bottom where it accumulates in the bottom of the tank. This air also contains organic components (micro-organisms, bacterial growth, fungal growth, enzyme activity, yeast, mold, pollen and other microbial organic components), and dirt, grit, and other particulates, all of which, in their own special way, contribute to:

- fuel degradation

- clogged fuel filters

- excessive exhaust smoke

- component failure (fuel pumps and injectors)

- formation of acids

- floating debris in the tank

- sludge build-up in the tank

- foul odors emitting from the tank

Keeping water out of the tank is the most important undertaking required to maintain good fuel, extend the life of filters and engine components, and assuring high operating efficiency and low operating costs are maintained with the use of your diesel powered equipment. Not following Best Management Practices, such as making sure fuel tank caps are on tight and have a good seal, and vent pipes are not open to catch rain goes a long way, but doing nothing about the flow of air into and out of your fuel tank contributes greatly to fuel problems.

Although having a protocol in place that calls for checking fuel tanks periodically for water accumulation (such as the use of Kolor Kut Water Finding Paste) and removing any water that has accumulated should be an integral part of every Fuel Maintenance Plan, adopting a passive, “never sleeps”, component that prevents water, organic components and particulates from entering the fuel tank should be the first step in maintaining optimal fuel quality.

We offer two types of Desiccant Breathers that will provide you with an economic and convenient means of passively preventing contamination of your stored diesel fuel:

- Desiccant Standard Disposable Breathers – For tanks up to 500 gallons (1,900 liters)

- Rebuildable Steel Desiccant Breathers – For tanks larger than 500 gallons (1,900 liters)

Ideal for Basic Protection from Moisture and Particulate Contamination in Lubricant and Equipment:

Totes

Transformers

Storage Tanks

Hydralics

Typical Industries:

Power Generation

Mining

Aviation

Storage

Manufacturing

Petrochemical

Desiccant Disposable

Fuel Tank Breathers

Specifications

Sizing *

Sizing *

Sizing *

Sizing *

Sizing *

Components of the

Miniature Disposable Desiccant Breather (the DC-BB & DC-1)

Components of the Standard Disposable Desiccant Breather ( the DC-2, DC-3 & DC-4)

Des-Case Standard Disposable

Desiccant Breathers

For Fuel Tanks Up To 500 Gallons (1,900 liters)

(See Below for larger capacity tanks)

What Are Desiccant Vent Breathers?

Des-Case Disposable Standard Breathers are simple, yet dependable protection. The outer body is a resiliant clear polycarbonate providing bi-directional, controlled airflow incorporating a water vapor absorbent and multi-tiered particulate filtration to 3-micron absolute. As the silica gel absorbs water from incoming air, the color changes from blue to pink indicating that the breather has reached capacity, allowing for ease in monitoring when replacement is needed.

The use of a Des-Case Standard Disposable Desiccant Vent Breather will absorb moisture from the air being drawn into the fuel tank as well as filter the air of particulates, dirt, and the organic components, bacterial and fungal growth present in the air. Just like you would not consider operating your diesel equipment without an air intake filter, you should not think twice about the importance of assuring clean, dry air is being pulled into your fuel tank, especially in any operations located in high humidity regions, near bodies of water, or locals or operations such as farming, construction, mining or marine operations.

Des-Case Standard Breathers provide simple, yet dependable protection from moisture and particulate contamination. These versatile breathers are five times more effective than the leading non-desiccant breathers, providing optimal defense against humidity and air-borne particulates from contaminating your fuel tank or your equipment component’s lubrication reservoirs. Prevention trumps corrective action.

With a wide range of sizes and features for almost any application and industry, Des-Case breathers simultaneously remove moisture from equipment and storage tanks with silica gel and prevent even the smallest particles from entering your fuel tanks with multi-layer filtration.

The best part is you’ll see a return on investment almost immediately. With fewer breakdowns, production stoppages, and reduced preventative maintenance costs you’ll run more efficiently and create less waste, all while increasing the working life of your equipment.

These disposable Standard Breathers provide simple, yet dependable protection from moisture and particulate contamination in equipment and fuel storage tanks. Five times more effective than the leading non-desiccant breathers, they provide optimal defense against humidity for your application.

Benefits

- Removes moisture in the headspace of equipment

- Eliminates rust-forming condensation

- Prevents sludge deposits and water-contaminated fuel

- Prevents contamination ingress

- Provides longer lubricant life

- Reduces wear and tear on equipment and prolongs component life

HOW IT WORKS

The Des-Case desiccant breather replaces the standard dust cap or OEM breather cap on equipment. As air is drawn into equipment through the breather, the layered filter elements remove particulate while the desiccant beads strip harmful moisture. While in service or during shut-down, the desiccant beads attract moisture from inside the equipment reservoir, actively drying the equipment.

The Des-Case desiccant breather replaces the standard dust cap or OEM breather cap on equipment. As air is drawn into equipment through the breather, the layered filter elements remove particulate while the desiccant beads strip harmful moisture. While in service or during shut-down, the desiccant beads attract moisture from inside the equipment reservoir, actively drying the equipment.

A pink breather means it has done its job keeping moisture out of your fuel or lubricants. Time to replace the breather with a new one.

APPLICATIONS:

Compatible with all mineral oils, most synthetic oils and diesel.

- Small Fuel Storage Tanks

- Equipment Fuel Tanks

- Emergency Generator Tanks

- Totes

- Storage Drums

- Engine and other component lubrication reservoir

- Remote Applications

Des-Case Standard Breathers are designed for use in a wide range of locations and applications. Recommended temperature range is -20 deg F (-29 deg. C) to 200 deg. F (93 deg. C).

Sizing Breathers to Your Tank

To determine what size Desiccant Vent Breather is right for your particular application or tank size, see the Breather Sizing Chart.

OPERATING ENVIRONMENTS:

- General Use

- Indoors

- Cold Weather Environments

- High Humidity

- Wash-downs

Trouble Shooting Tank Contamination

Desiccant Breathers absorb moisture from the air as the air enters the tank. This is the primary purpose for incorporating a Desiccant Breather into your fuel or oil lubricant tank maintenance program.

Most often the moisture is being drawn into the tank from outside the tank as the fuel is consumed from the tank. The fuel is replaced by the air drawn in through the breather. The air is drawn into the breather through the underside of the breather through the internal filter, with the air passing up through the desiccant material, and then down the central tube into the tank. Because the air passes through the desiccant material at the bottom and the moisture is absorbed by this desiccant material, this material changes to pink first. This is the normal operation of the desiccant breather.

Most often the moisture is being drawn into the tank from outside the tank as the fuel is consumed from the tank. The fuel is replaced by the air drawn in through the breather. The air is drawn into the breather through the underside of the breather through the internal filter, with the air passing up through the desiccant material, and then down the central tube into the tank. Because the air passes through the desiccant material at the bottom and the moisture is absorbed by this desiccant material, this material changes to pink first. This is the normal operation of the desiccant breather.

Alternatively, if the desiccant material changes from blue to pink at the top first, as pictured here, the source of the water is internal to the system. This could be a sign that water has entered the tank via another means (not through the breather) such as from a badly sealing fill cap leaking water from rain, or a fill cap being left off by mistake. Some lubricating oil tanks may experience a leak from a water cooler (if present).

Alternatively, if the desiccant material changes from blue to pink at the top first, as pictured here, the source of the water is internal to the system. This could be a sign that water has entered the tank via another means (not through the breather) such as from a badly sealing fill cap leaking water from rain, or a fill cap being left off by mistake. Some lubricating oil tanks may experience a leak from a water cooler (if present).

This color change at the top could also be a sign of a common situation where fuel or lubricating oil that has previously been contaminated with water is added to the tank. As this fluid becomes heated, moisture enters the air inside the tank and is expelled through the breather. The color change at the top of the breather occurs near where the center tube interacts with the desiccant material, indicating the moisture is exiting the tank and being absorbed by the desiccant material.

The volume of water inside the tank is often much higher than what the breather can remove and this color change from the top of the breather indicates more investigation is necessary to determine further corrective actions which may include pumping out the water collected at the tank bottom.

Miniature Disposable Desiccant Breather (DC-BB & DC-1) Components (Pictured at the Left)

The Following is a list of the components of the Standard Disposable Desiccant Breather as pictured to the left:

- WATER VAPOR ADSORBENT — Silica gel adsorbs water from incoming air and can hold up to 40% of its weight. Condition is indicated by change of color from blue to light pink.

- FILTER ELEMENTS — Polyester filter elements at the top and bottom of the breather remove airborne contamination. Unique loops allow particles to release during system exhalation, helping increase breather life.

- FOAM PADS — Foam filters at the top and bottom of the breather capture oil mist and disperse incoming air evenly over filtration and drying areas.

- CHECK-VALVES — High-quality umbrella check-valves that won’t clog or stick are located underneath the unit for added protection from wash down environments. Check-valves isolate equipment from ambient condition, prolonging breather life and protecting system integrity. Available in Extended Series, Extreme Duty, VentGuard, and HydroGuard breathers.

- RUGGED HOUSING — Shock-absorbing polycarbonate casing provides reliable service and easy maintenance on most breathers. Extreme Duty breathers are constructed from a polycarbonate/polybutylteraphtalete alloy for additional strength and chemical compatibility.

- INTEGRATED STANDPIPE — The integrated nylon standpipe provides excellent vibration resistance and dissipates impact throughout the unit, eliminating weak points. It also allows even airflow distribution throughout the unit, eliminating inaccurate readings of desiccant saturation.

- HONEYCOMB OIL MIST REDUCER — The oil mist reducer is situated inside the standpipe, made from polypropylene for maximum chemical compatibility. Mimicking nature’s intricate honeycomb design, this feature allows oil mist to coalesce and drain back into the reservoir, rather than compromising the desiccant. Available in Extended Series breathers.

- THREADED MOUNTING — Internal or external threaded mount allows for durability and stability and easily replaces standard breather caps with one of several adapters.

Standard Disposable Desiccant Breather (DC-2, DC-3 & DC-4) Components (Pictured at Left)

- Domed Cap — A domed cap allows for better wash-down runoff

- Integrated Nylon Standpipe — The integrated standpipe provides excellent vibration resistance and dissipates impact throughout the unit, eliminating weak points. It also allows even airflow distribution throughout the unit, eliminating inaccurate readings of desiccant saturation.

- External Ribs — External ribs on shell to create greater durability and grip when installing or replacing breather

- Integrated Drip Ring — An integrated drip ring keeps shedding water from entering the vent holes

- Threaded Mounting — Easily replaces standard filler/breather cap with multi-fit connection or one of several adapters.

- Air Vents — Individual air intakes are opened based on flow requirements of the system. Plugs protect unit during shipping and storage.

- Foam Pad — Foam filter captures any oil mist and disperses incoming air evenly over filtration and drying areas.

- Filter Element — Polyester filter element removes airborne contamination to 3-micron absolute. Unique loops allow particles to release during system exhalation, helping to increase breather life.

- Enhanced Seal — An enhanced seal eliminates potential for airflow bypass

Customized Desiccant Options

Although every element of Des-Case breathers has been designed to work in a wide variety of industries, we understand that each environment, application, and lubricant can be unique. That ‘s why Des-Case offers several alternative media options that you can customize for your specific needs. Any of Des-Case’s desiccant breathers can be customized with your choice of absorbent media

Silica gel, used in our Miniature Disposable and the Standard Disposable Desiccant Breather, is the most efficient and economic moisture absorbent for general applications. Des-Case offers two types of indicating silica gel, blue-to-pink or orange-to-white.

Other desiccant options include:

- Molecular sieve has high efficiency at low levels of humidity. It is best for drying highly polar alcohols, unsaturated hydrocarbons, and static dehydration of gas.

- Activated carbon is an ideal absorbent in applications requiring fume mitigation or air purification.

- Activated alumina is most effective in removing organic acids, especially those that are larger in size.

Standard Buna-N® O-Ring Material may be replaced with the following alternative options:

- Vitron®

- EPDM

Contact us if your application requires a more specialized option to address your needs.

Rebuildable Steel

Desiccant Breather

Specifications

Model

DC-RS-3

Unit Height

11.5" / 292 mm

Unit Diameter

10.13" / 257.2 mm

Unit Operating Weight (Dry)

16 lbs / 7.26 kg +/-

Connection Size

2" NPT

Amount of Silica Gel

3 lbs / 1.36 kg

Max. Flow Rate

85 @ 0.5 psid

Filter Efficiency

1µ absolute

(β₁≥1000)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-5

Unit Height

13.75" / 349 mm

Unit Diameter

2.52" / 64.1 mm

Unit Operating Weight (Dry)

20 lbs / 9.07 kg +/-

Connection Size

2" NPT

Amount of Silica Gel

5 lbs / 2.27 kg

Max. Flow Rate

85 @ 0.5 psid cfm

Filter Efficiency

1µ absolute (β₁≥1000)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-9

Unit Height

18.25" / 464 mm

Unit Diameter

10.13" / 257.2 mm

Unit Operating Weight (Dry)

27 lbs / 12.25 kg +/-

Connection Size

2" NPT

Amount of Silica Gel

9 lbs / 4.08 kg

Max. Flow Rate

80 @ 0.5 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-15

Unit Height

19.25" / 489 mm

Unit Diameter

15.5" / 393.7 mm

Unit Operating Weight (Dry)

49 lbs / 22.23 kg +/-

Connection Size

3" NPT

Amount of Silica Gel

15 lbs / 6.80 kg

Max. Flow Rate

205 @ 0.5 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-25

Unit Height

22.5" / 571 mm

Unit Diameter

15.5" / 393.7 mm

Unit Operating Weight (Dry)

64 lbs / 29.03 kg +/-

Connection Size

3" NPT

Amount of Silica Gel

25 lbs / 11.34 kg

Max. Flow Rate

140 @ 0.5 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-50

Unit Height

31.25" / 794 mm

Unit Diameter

15.5" / 393.7 mm

Unit Operating Weight (Dry)

100 lbs / 45.36 kg +/-

Connection Size

3" NPT

Amount of Silica Gel

50 lbs / 22.68 kg

Max. Flow Rate

115 @ 1 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-75

Unit Height

39.75" / 1010 mm

Unit Diameter

15.5" / 393.7 mm

Unit Operating Weight (Dry)

144 lbs / 65.32 kg +/-

Connection Size

3" NPT

Amount of Silica Gel

75 lbs / 34.02 kg

Max. Flow Rate

80 @ 1 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-100

Unit Height

31" / 787 mm

Unit Diameter

23.5" / 596.9 mm

Unit Operating Weight (Dry)

190 lbs / 86.18 kg +/-

Connection Size

4" NPT

Amount of Silica Gel

100 lbs / 45.36 kg

Max. Flow Rate

270 @ 1 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-150

Unit Height

36.75" / 933 mm

Unit Diameter

23.5" / 596.9 mm

Unit Operating Weight (Dry)

190 lbs / 68.04 kg +/-

Connection Size

4" NPT

Amount of Silica Gel

150 lbs / 68.04 kg

Max. Flow Rate

250 @ 1 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

Model

DC-RS-200

Unit Height

42.75" / 1086 mm

Unit Diameter

23.5" / 596.9 mm

Unit Operating Weight (Dry)

200 lbs / 90.72 kg +/-

Connection Size

4" NPT

Amount of Silica Gel

200 lbs / 90.72 kg

Max. Flow Rate

240 @ 1 psid cfm

Filter Efficiency

1µ absolute (β₃≥200)

Operating Temp.

Range (°F)

-20° to 220°

Operating Temp.

Range (°C)

-29° to 104°

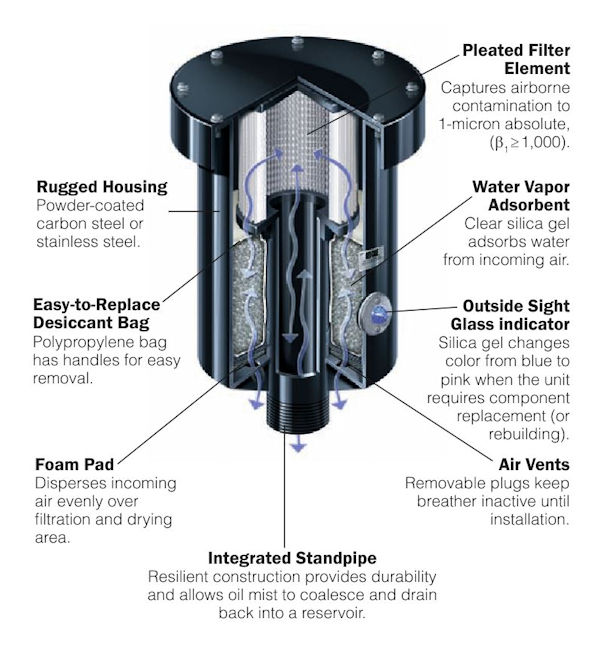

Rebuildable Steel

Breather Components

Rebuildable Steel Des-Case Desiccant

Fuel Tank Breathers

For Tanks Larger Than 500 Gallons (1,900 liters)

Rebuildable Steel Breathers were designed specifically for applications such as bulk storage tanks or large circulating systems with very high temperatures, extremely polluted air, or a corrosive environment. They are ruggedly designed with housings of powder-coated carbon steel or stainless steel. Rebuildable steel breathers accommodate large air flow rates with minimal pressure drops. Contact us for more information and pricing for 304 Stainless Steel or 316 Stainless Steel Rebuildable Des-Case Breathers.

As wet, dirty air is drawn through the unit, the hygroscopic agent extracts moisture and a 1-micron micro-glass pleated filter element removes solid particulate. When the air is expelled from the container, the foam pad cleans itself by releasing dirt back into the atmosphere. The hygroscopic agent is partially reactivated by the dry air passing back through, thereby permitting longer periods between replacing components (or rebuilding).

As wet, dirty air is drawn through the unit, the hygroscopic agent extracts moisture and a 1-micron micro-glass pleated filter element removes solid particulate. When the air is expelled from the container, the foam pad cleans itself by releasing dirt back into the atmosphere. The hygroscopic agent is partially reactivated by the dry air passing back through, thereby permitting longer periods between replacing components (or rebuilding).

The replacement filter element captures airborne contamination to 1-micron absolute. The Desiccant Bag Filter is a polypropylene bag that has handles for easy removal and replacement containing the clear silica gel that absorbs water from incoming air. The Outside Sight Glass Indicator has silica gel visible that changes color from blue to pink when the unit requires rebuilding.

Applications:

- Bulk Storage

- Diesel Tank Storage

- High Flow Applications

- Large Hydraulic Reservoirs

- Chemical Tanks

Sizing Breathers to Your Tank

To determine what size Desiccant Vent Breather is right for your particular application or tank size, see the Breather Sizing Chart.

Operating Environments:

- Harsh Environments

- Harsh Chemicals

- High Temperature

Large Tank Applications:

Special purpose large tank installations of Desiccant Breathers are accomplished with a manifold arrangement that provides the required air flow.

Rebuild Kits for the

Steel Rebuildable

Desiccant Breathers

Each Rebuild Kit consists of a Replacement 1-micron Pleated Filter Element, Desiccant Bag Filter, Sight Glass Indicator, Gasket, and Foam Pad which are easily replaced without removing the breather from service.

Note that Rebuild kits are available in a variety of materials to meet chemical compatibility needs. Desiccant bags above RS-25 are packaged in 26 lb. increments for easy handling. It is recommended use of a pressure/relief on any tank or storage system.