Water Eliminator Removes Water

From Diesel Fuel Tanks

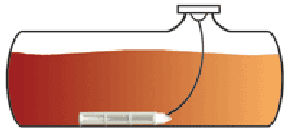

The 12 inch (30.48 cm) Water Eliminator lies on the tank bottom and absorbs accumulated water

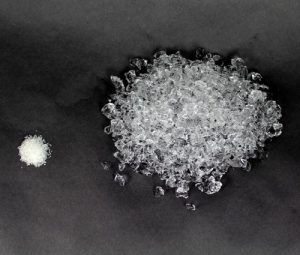

Water Eliminator crystals are water specific and will swell many times their weight in water. Water specific means they will only absorb the water in your tank and will not absorb or adversely affect gasoline, diesel fuel, fuel oil, JP5 or hydraulic oil.

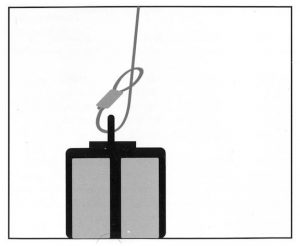

Thread lanyard loop through hole in the top of the cap, and run snap hook through loop. Pull tight.

Attach the snap hook to the safety retention chain on the fuel cap. Slowly lower cartridge until it rests flat on the bottom of the tank. Check the cartridge in 6 to 12 hours to see if it has filled with water. If it is full replace with a new cartridge. If not, lower it back into the tank and check with each fuel fill-up.

Advertisement

Water Eliminator Removes Water from Gasoline, Diesel Fuel, Fuel Oil, JP5 and Hydraulic Fluid Tanks

New High Pressure Common Rail (HPCR) injection system designs that are incorporated into today’s diesel engines require clean fuel to operate at full potential. These engines are designed to be more efficient, but they cannot maintain optimal performance and reliability using degraded or contaminated fuel. The most common contaminant in diesel fuel is water. The Water Eliminator will remove water from diesel fuel storage tanks.

When an engine is providing less than peak performance or engine maintenance reveals clogged fuel filters, excessive exhaust smoke, or other symptoms of a performance problem, the problem typically lies in the fuel tank.

Fuel Deterioration a Natural Process

Fuel degradation is a natural process that causes the formation of sediment, sludge, and acids in the fuel. Historically, diesel fuel would remain stable for years and engine performance problems that could be traced to the diesel fuel were few. Many diesel mechanics did not even consider fuel quality or contamination issues when diagnosing performance problems or component failures. Fuel problems, however, are now more common as oil refining processes changed to accommodate adoption of Ultra Low Sulfur Diesel (ULSD). In addition, users of bio-fuels suffer from an even more dramatic increase in fuel re-polymerization that causes rampant problems including:

- filter plugging

- fuel injector failures

- reduction in stored fuel shelf life

With today’s fuels, the degradation process of stored fuel can reach the problem stage in as little as six months. Degradation is further accelerated by the extreme pressure of HPCR engines, temperature change, water, and microbial contamination.

Gasoline suffers from a similar problem. Separation of water from gasoline containing ethanol is well documented and can cause serious damage to gasoline engines, whether in automobiles, marine, or small engine applications.

Extend Stored Diesel Fuel and Gasoline Shelf Life

A critical part of a Fuel Management Program to extend diesel and gasoline engine life and assure peak performance is as simple as keeping water out of the fuel. Water is a common problem, and many believe an inevitable problem. But simple and inexpensive steps taken to assure that water is not allowed to collect in the fuel pays great dividends.

Simple steps, like not leaving the fuel cap off a storage tank, or periodically checking the fuel tank with a rod and Kolor Kut Water Finding Paste, will go a long way to keeping the water out of a fuel tank. But water gets into a fuel tank in many ways. Sometimes it is introduced at your local filling station or by your fuel distributor.

When diesel fuel or gasoline is loaded from the central storage tanks to a transport truck tanker when the fuel level in those tanks is low or the load out is performed shortly after the tanks have been filled, water in the tank bottom that has been stirred up is loaded into the tanker truck with the fuel, and delivered to the service station tank with the fuel.

Day Tanks and Equipment Tanks

But also, water is introduced to your fuel tank while you operate your equipment. As a tank of fuel is used, the tank pulls air into the tank through a vent breather to replace the space in the tank previously occupied by the fuel. Moisture in the air drawn into the tank condenses on the sides of the tank. Over time, this water accumulates in the tank bottom.

If you have equipment that is used seasonally or intermittently, you are exposed to the problems of water accumulation in fuel tanks. Fuel will expand and contract as the ambient temperature changes. This causes the fuel in your tank to push air out of the tank in periods of expansion, and draw air into the tank during periods of contraction. This “breathing” of the tank draws air into the tank that contains moisture that can form into water droplets and accumulate in the bottom of your fuel tank.

Tank Vent Breathers Prevent Moisture Intrusion

An additional tool that is available to prevent moisture, microbial, fungal, and particulate contamination from entering the fuel tank through the tank breather vent is the Desiccant Breather. Visit our Desiccant Breather page for additional information.

Critical Winter Season Maintenance

This water can be a problem in numerous respects. Water freezes in the winter. It can accumulate to the point where the fuel line from the tank to the engine accumulates water and can freeze where water lies in low sections of the fuel line. Also, water that accumulates in the fuel filter can freeze. Diesel Fuel Recovery, a product for reversing this cold-weather problem that impacts diesel fuel, is available on this website, can be used in these situations to get the equipment back in operation.

Water Problems in Any Season

But more importantly, water can reach the engine and can cause engine component failure. This particular problem is common where the fuel tank experiences considerable movement, such as in marine applications, construction, farming, and off road applications. Water is the habitat of microbial and fungal contamination, and, in time, can cause filters to clog, engines to smoke, and acids from the reproduction process of these microbes to degrade tanks and engine components (i.e.: injectors).

The Water Eliminator

If you store gasoline or diesel fuel for use in equipment, operate a boat, RV, backup power generators, farming or construction equipment, you need the Water Eliminator®. It is the most cost effective way to remove water from Gasoline, Diesel Fuel, Fuel Oil, Kerosene or Hydraulic Fluid.

If you store gasoline or diesel fuel for use in equipment, operate a boat, RV, backup power generators, farming or construction equipment, you need the Water Eliminator®. It is the most cost effective way to remove water from Gasoline, Diesel Fuel, Fuel Oil, Kerosene or Hydraulic Fluid.

The Water Eliminator® presents an easy and economical solution for removing water from tanks used to store fuel, whether the tanks are installed on equipment, fuel stored in day tanks to meet surge demand, or larger storage tanks. Maintaining fuel free from water reduces the potential for microbial contamination and accumulation of sludge in tanks.

Larger Fuel Tanks

The WE-12 Water Eliminator® is 12 inches long and requires a 1.85 inch or greater tank opening and works in tank depths up to 2 meters. But use in larger tanks can be accommodated by using the included lanyard to string several WE-12 units together in a “daisy chain” arrangement.

Capturing Water

The Water Eliminator captures water directly from the fuel or oil in the tank. The crystals contained inside the Water Eliminator are water specific and will swell encapsulating the water until the cartridge is full. The Water Eliminator® helps to prevent service problems related to water contamination including: Plugged Fuel Filters, Fuel Line Freeze-up, Damaged Fuel Pumps and Injectors, Corrosion, Damaged Injectors, Growth of Microbial Contamination, Loss of Power, Corrosion, and Down Time.

When used in mobile equipment, check your Water Eliminator® at each fuel stop. If the unit is empty, your tank is water free. Leave it in place until nearly full, then discard in a proper receptacle and replace it with a new one. (Disposal in accordance with local and federal regulations.)

How the Water Eliminator Works

The units contain a water adsorbent polymer that captures free or emulsified water on contact when placed in the fuel tank.

The WE-12 Water Eliminator

The WE-12 Water Eliminator package contains one 12 inch long (not including the hole on one end for securing the lanyard) cartridge. Also included are two lengths of stainless steel lanyards, each 39 inches (one meter) in length. It is ideal for use in:

The WE-12 Water Eliminator package contains one 12 inch long (not including the hole on one end for securing the lanyard) cartridge. Also included are two lengths of stainless steel lanyards, each 39 inches (one meter) in length. It is ideal for use in:

- heavy duty trucks with saddle tanks

- construction equipment

- farm equipment

- generators

- marine applications

- fuel storage tanks

- home heating oil tanks

- fuel transfer tanks

- any equipment operated in extremely cold environments

A 1.85″ (4.7cm) or greater tank opening is required. The fuel filler pipe must allow direct access to the bottom of the tank. The Water Eliminator unit is not designed to be withdrawn around bends. For tanks that are greater than 72″ (182.88cm) in depth an additional lanyard will be required.

Installing the WE-12

The WE-12 Water Eliminator has a cylindrical injection molded nylon “skeleton” with several longitudinal and circumferential ribs. They are ultrasonically welded and surround a filter screen that contains the absorptive crystals. This construction retains its shape after the crystals have absorbed its full capacity of water. It will not deform or impede removal from the tank opening. Beware competing products that utilize a fiber or cloth bag with the crystals secured inside. There are often sharp edges on the inside of the fuel tank or on the chain that secures the fuel cap. These can rip the fiber and spill the crystals into the bottom of the tank. Also, the flexible bag does not constrain the expanding crystals. Sometimes they expand to a circumference larger than the tank opening. This makes removal difficult or impossible without ripping the cloth bag.

Each Water Eliminator includes two lanyards with a loop on one end and a snap hook on the other. One lanyard is required for tanks up to 36 inches in height. Loop the lanyard to the WE-12 as shown in the pictures to the left and connect the other end, using the snap hook, to the safety retention chain on the fuel cap. For tanks up to 78 inches in height, use the second lanyard to tether the WE-12 Water Eliminator. For tanks larger than 78 inches in height, use additional lanyards. The WE-12 Water Eliminator must lie flat on the bottom of the tank. A rod inside the WE-12 Water Eliminator provides weight and assures that the unit will stay on the bottom of the tank.

Water Eliminator Cautions

For optimal results, we recommend to not use additives which contain water dispersants when using the Water Eliminator®. The Water Eliminator® insert should be removed from the tank in less than sixty days. The manufacturer is not liable for damages resulting from improper use of the product.

WARNING — ATTENTION — ADVERTENCIA

![]() This product can expose you to chemicals including Acrylamide, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

This product can expose you to chemicals including Acrylamide, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

Ce produit peut vous exposer à des produits chimiques, y compris l’acrylamide, qui est connu dans l’État de Californie pour causer le cancer et des malformations congénitales ou d’autres problèmes de reproduction. Pour plus d’informations, allez à www.P65Warnings.ca.gov

Este producto puede exponerlo a productos químicos como la acrilamida, que en el estado de California es causante de cáncer y defectos de nacimiento u otros daños reproductivos. Para más información ve a www.P65Warnings.ca.gov