MTC Series Mobile Fuel Polishing

and Tank Cleaning Systems

Specifications for the

MTC Cart Mounted and

the MTC HC Pallet

Mounted Systems

MTC 1000 Cart Mounted Mobile Fuel Polishing Systems

Nominal Flow Rate

15 GPM / 900 GPH (57 LPM / 3,400 LPH) – At 50 Hz, nominal flow rate decreases to 12 GPM / 720 GPH (45.4 LPH / 2725 LPH)

Fuel Treated in 8 Hours

Up to 7,200 gallons (Up to 27,500 Ltr)

Pump / Motor

1/2 HP Single Phase, Continuous Duty, Thermally Protected (TEFC)

Pump

Self Priming Rotary Vane Pump

Power

120V / 60Hz / 15A or 230V / 50Hz / 15A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Port Size

1″ Male Cam & Groove Inlet – 1″ Male Cam & Groove Outlet

Plumbing

Stainless Steal

Suction Hose

1″ Clear Reinforced 25 ft (7.6 m) length

Discharge (Pressure) Hose

1″ 25 ft (7.6 m) length

Filtration Controller

Manual Switch

Multi-Phase Diverter

Ball Valve

Secondary Filtration

Spin-On Filter

Secondary Filter Elements

Construction

Aluminum Two-Wheel Cart with Aluminum, Powder Coated Back Plate & Spill Tray

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Weight

160 lbs +/- (72.6 kg)

Dimensions

(H x W x D)

48″ x 22.5″ x 25″

(122 x 57 x 63 cm)

Not for use with fluids that have a flash point below 100 deg. F.

MTC X Cart Mounted Mobile Fuel Polishing Systems

Nominal Flow Rate

26 GPM / 1,560 GPH (98 LPM / 5,880 LPH) 120V / 60Hz — 20.8 GPM / 1,248 GPH (78.7 LPM / 4,722 LPH) 230V / 50Hz

Fuel Treated in 8 Hours

Up to 12,480 gallons (Up to 47,000 Ltr)

Motor

3/4 HP Single Phase, Continuous Duty, Thermally Protected (TEFC)

Pump

Self Priming Rotary Vane Pump

Power

120V / 60Hz / 15A or 230V / 50Hz / 15A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Plumbing

Black Iron

Port Size

1 1/2″ Male Cam & Groove Inlet – 1 1/4″ Male Cam & Groove Outlet

Suction Hose

1 1/2″ Clear Reinforced 25 ft (7.6 m) length

Discharge (Pressure) Hose

1 1/4″ 25 ft (7.6 m) length

Filtration Controller

Manual Switch

Multi-Phase Diverter

Ball Valve

Secondary & Tertiary Filtration

Spin-On Filters

Secondary & Tertiary Filter Elements

Construction

Aluminum Two-Wheel Cart with Aluminum, Powder Coated Back Plate & Spill Tray

Suction Capability (Primed)

15 ft. Vertical lift or 100 ft. horizontal run (lines > 1.5″)

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Weight

185 lbs +/- (84 kg)

Dimensions

(H x W x D)

48″ x 22.5″ x 25″

(122 x 57 x 63 cm)

Not for use with fluids that have a flash point below 100 deg. F.

MTC HC-50 High Capacity Pallet Mounted Mobile Fuel Polishing Systems

Flow Rate

Variable Rate: 25 to 75 GPM (95 to 284 LPM) / 1,500 to 4,500 GPH (5,675 to 17,000 LPH)

Fuel Treated in 8 Hours

Up to 36,000 gallons (Up to 136,000 Ltr)

Pump

Adjustable Flow Rate Air Driven, Double Diaphragm Pump (Customer Supplied Pressurized Air Source)

Air Supply Connection

Air Powered (25 – 50 SCFM @ 90psi – 1/2″ Air Hose Connection

Power

None for Basic Operation

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Port Size

2″ Male Cam & Groove Inlet – 2″ Male Cam & Groove Outlet

Suction Hose

2″, Clear Reinforced 25 ft (7.6 m) length

Discharge (Pressure) Hose

2″, 25 ft (7.6 m) length

Filtration Controller

Manual Switch (Optional SFC-50 Programmable Controller – requires 110V 60HZ 15A)

Secondary Filter Elements

N/A

Tertiary Filter Elements

Skid Construction

Powder Coated Carbon Steel Lifting Eyes & Forklift Channels – Dry Tray with Drain

Suction Capability (Primed)

15 ft. Vertical lift or 100 ft. horizontal run (lines > 1.5″)

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Weight

630 lbs +/- (286 kg)

Dimensions

(H x W x D)

59″ x 36″ x 45″

(150 x 91 x 114 cm)

Not for use with fluids that have a flash point below 100 deg. F.

MTC HC-90 High Capacity Pallet Mounted Mobile Fuel Polishing Systems

Flow Rate

Variable Rate: 10 to 90 GPM (38 to 340 LPM) / 600 to 5,400 GPH (2,270 to 20,400 LPH)

Fuel Treated in 8 Hours

Up to 43,200 gallons (Up to 163,530 Ltr)

Pump

3 HP Single Phase Direct Coupled Sliding-vane Positive Displacement Pump with Viton Seals

Power

208-230V 60Hz 20A Single Phase, or 230V 50Hz Single Phase, 240V 60Hz 20A Three Phase or 480V 60Hz 12A Three Phase

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Port Size

2″ Male Cam & Groove Inlet – 2″ Male Cam & Groove Outlet

Suction Hose

2″ Clear Reinforced 25 ft (7.6 m) length

Discharge (Pressure) Hose

2″ 25 ft (7.6 m) length

Instrumentation & Automation

Vacuum Gauges on Primary Filter, Pressure Gauge on Pump Discharge Pressure, Gauges on Secondary Filter, AXI Watect 550 Water Sensor Alarm Module (Standard)

Multi-Phase Diverter

Ball Valve

Secondary Filter Elements

N/A

Tertiary Filter Elements

Skid Construction

Powder Coated Carbon Steel Lifting Eyes & Forklift Channels – Dry Tray with Drain

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Weight

710 lbs +/- (322 kg) (Depending on Configuration)

Dimensions

(H x W x D)

59″ x 36″ x 45″

(150 x 91 x 114 cm)

Not for use with fluids that have a flash point below 100 deg. F.

MTC HC-150 High Capacity Pallet Mounted Mobile Fuel Polishing Systems

Flow Rate

Variable Rate: 10 to 150 GPM (38 to 568 LPM) / 600 to 9,000 GPH (2,270 to 34,000 LPH)

Fuel Treated in 8 Hours

Up to 72,000 gallons (Up to 272,500 Ltr)

Pre-Filter Skid

Primary Filtration

Secondary Filtration

Port Size

3″ Male Cam & Groove Inlet – 2 1/2″ Male Cam & Groove Outlet

Suction Hose

2″ Clear Reinforced 25 ft (7.6 m) length

Interconnection Hose

2 1/2″ 10 ft (3.05 m) length

Skid Construction

Powder Coated Carbon Steel Lifting Eyes & Forklift Channels – Dry Tray with Drain

Dimensions

(H x W x D)

36″ x 45″ x59″

(91 x 114 x 150 cm)

Pump & Secondary Skid

Pump

3 HP Single Phase Direct Coupled Sliding-Vane Positive Displacement Pump with Viton Seals – 2 1/2″ Ports

Power

480V 50/60Hz 20A Three Phase

Port Size

2 1/2″ Male Cam & Groove Inlet – 2 1/2″ Male Cam & Groove Outlet

Port Size

2 1/2″ Male Cam & Groove Inlet – 2″ Male Cam & Groove Outlet

Tertiary Filter Elements

Instrumentation & Automation

Vacuum Gauges on Primary Filter, Pressure Gauge on Pump Discharge Pressure, Gauges on Secondary Filter, AXI Watect 550 Water Sensor Alarm Module (Standard)

Discharge (Pressure) Hose

2 1/2″ 25 ft (7.6 m) length

Skid Construction

Powder Coated Carbon Steel Lifting Eyes & Forklift Channels – Dry Tray with Drain

Dimensions

(H x W x D)

36″ x 45″ x59″

(91 x 114 x 150 cm)

Weight

900 lbs +/- (408.2 kg) (Depending on Configuration)

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Not for use with fluids that have a flash point below 100 deg. F.

MTC HC-300 High Capacity Skid Mounted Mobile Fuel Polishing Systems

Flow Rate

Variable Flow up to 300 (1,135 LPM) / 18,000 GPH (68,000 LPH)

Fuel Treated in 8 Hours

Up to 144,000 gallons (Up to 545,000 Ltr)

Primary Filtration

Bag Filter Configured to use Four Filter Bags – Carbon Steel Vessel, Davit Arm Swing Cover

Secondary Filtration

Two FV-300 (Viking 3F) High Volume Filter Vessels – Carbon Steel Filter Housing, Quick Relese Four Bolt Swing Cover, Drain Valve & Air Vent

Secondary Filtration Media

Filter Elements Available

Port Size

4″ Inlet, 4″ Outlet

Suction Hose

4″ Reinforced 25 ft (7.6 m) length

Discharge Hose

4″ Reinforced 25 ft (7.6 m) length

Connectors

Cam & Groove Fittings with Covers

Pump

Blackmer 4″, Sliding-vane, Positive Displacement, Viton Seals, 15HP Motor, 18.3 FLA

Power

480V 50/60Hz 30A Three Phase

Fuel Conditioner

Inline 4″ Magnetic Fuel Conditioner

Filtration Controller

Fully Automated UL508a SMART Filtration Controller (Optional Digital Text Readout)

Instrumentation & Automation

Vacuum Gauges on Primary Filter, Pressure Gauge on Pump Discharge Pressure, Gauges on Secondary Filter (Optional AXI Watect 550 Water Sensor Alarm Module)

Skid Construction

Powder Coated Carbon Steel, Filter Service Deck, and 200 Gallon Drip Tray with Drain

Dimensions

(H x W x D)

96″ x 54″ x 82″

(244 x 137 x 208 cm)

Weight

5,500 lbs +/- (2,495 kg)

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil, water, antifreeze

Operating Temperature

41 – 104 deg. F (5 – 40 deg C)

Not for use with fluids that have a flash point below 100 deg. F.

Frequently Asked

Questions

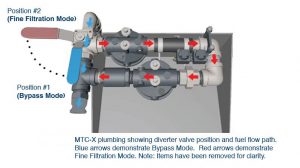

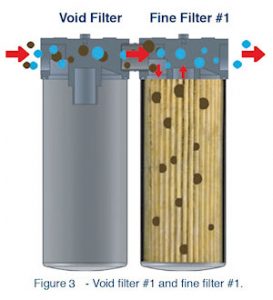

The Secondary and Tertiary Filters for the MTC-X Cart Mounted Mobile Fuel Polishing and Tank Cleaning System are spin-on filters for fine filtration down to 1 micron or for a Water Block coalescing filter down to 3 micron. See the graphic below. The filter that is supplied with the MTC-X System in the Secondary Filtration position is a spin-on filter housing without any element inside the metal container, known as a Void Canister. This allows use of a single filter in the Tertiary position.

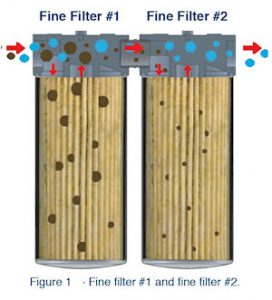

Fine Filtration Mode can be engaged during operation by changing the position of the ball valve to position 2. This will divert the flow of fuel through the spin-on filtration plumbing. The fuel will enter filter #1 first (void filter if only using single filter) and then flow through filter #2. When the system is in Fine Filtration Mode utilizing two (2) filters, it is important to install the filters in the correct order. The higher micron rated filter should be installed as filter #1, and the lower micron rated filter should be installed as filter #2. This process removes larger particulate, then fine particulate (or water), as shown in Figures A, B & C.

The filter housing includes two gauges that reads the differential pressure and, when the back-pressure increases indicating that the flow of fuel is being restricted by the accumulation of particulates or other debris on the filter element inside the spin-on filter, it is time to change the filter. This assures that you are not leaving a filter on too long, compromising the filtration process, or changing the filter too soon and not receiving all the value for the filter and increasing your operating costs.

In addition, the MTC-X has a vacuum line to remove fuel from the filters when they need to be changed. With the MTC-X running, redirect the fuel flow using the ball valve to bypass the spin-on Secondary and Tertiary filters. A valve will open a vacuum line from the Primary Bag Filter connecting to the Secondary and Tertiary filter lines to pull fuel from the Spin-on Filters so that the fuel in the filters will drain down, reducing the amount of fuel in the filters allowing for little or no fuel to be spilled into the spill tray during the process of changing the filters.

For most applications where fuel is stored for future use, a circulation system that consistently maintains water-free fuel storage and fuel filtered to a particulate level of 10 microns is acceptable. Seven different filters are offered for the MTC Systems. The fine filter spin-on filter elements are rated at 1, 3, 10, 25 and a 3 micron filter that is an X-Glass element. Also offered are 3 and 10 micron Water Block Filter elements.

The 3 micron Water Block filter is usually the preferred filter for ongoing preventative maintenance. The WB3 filter element will remove free water and emulsified water from the fuel stream along with the removal of particulates. Most engine manufacturers want the fuel entering their engine to be filtered at 4 microns, removing particulates and organic debris from the fuel preventing these contaminants from causing problems with the tolerances of fuel injector systems. Although modern engines have a factory-provided filter, usually in the 4 micron range, supplying fuel to the filter that already meets these requirements will extend the life of the factory filter and also assure the fuel is in optimal condition for use in these highly developed injector systems. It is better to have the engine manufacturer’s filter be the last line of defense against contamination in stead of it being the only defense.

The solution to suspected microbial growth and the results of asphaltene agglomeration in your fuel is the application of LG-X Series Fuel Conditioning Technology. Fuel Conditioners, when installed in-line in your equipment fuel system, will reverse the process of fuel breakdown, prevent microbial growth, restore fuel filterability, enhance combustibility, and prevent clogged filters and tank sludge. Optimizing fuel droplet size results in combustion efficiency, improved filterability and lower operating costs. (For a detailed explanation of how the LG-X Series Fuel Conditioner performs, see the web page “Learn More About Magnetic Fuel Conditioning”)

The LG-X Series Fuel Conditioner will also disperse and return to solution the asphaltene clusters the result in stored fuel degradation and return the fuel to a clear and bright appearance, a process sometimes referred to as “Fuel Polishing”. (For additional information, see “Diesel Fuel Polishing”)

Operating on the principal of induction on the process of combining kinetic and magnetic energy to influence the behavior of electrons, the AXI Fuel Conditioner provides a powerful magnetic field and the flow of fuel provides the kinetic energy. The process of how the LG-X Series Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling.

As the LG-X Series Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the LG-X Series Fuel Conditioner. However, there are situations where the benefit of circulating your fuel through a magnetic unit has added benefit. Should the LG-X Series Fuel Conditioner be used in a situation where a fuel tank itself is in poor condition, where the tank may be rusted on the inside and rust flakes may be coming loose, the LG-X Series Fuel Conditioner would prevent the sharp metal flakes from progressing to the fuel filter where they may pierce the filter medium and allow unfiltered fuel to proceed to the fuel system. Also, should the source of your fuel be questionable, such as a marine vessel that fuels at island fuel stops with little oversight, or remote mining operations where a supplier may not be reliable, having the LG-X Series Fuel Conditioner installed to stop metal shavings or other ferrous debris that may be the result of maintenance on upstream distribution equipment could be a great benefit.

Should a fuel restriction that cannot be traced to a clogged filter element make the LG-X Series Fuel Conditioner suspect, you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. An extreme example is pictured to the left. A spare parts kit for the LG-X Series Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

To completely reverse the buildup of particulates and fuel components that have attached themselves to the fuel tank bottom and sides, the fuel system lines, and inside surfaces of engine components, combine the use of the LG-X Series Fuel Conditioner with regular use of AFC Series Fuel Catalyst and Tank Cleaning Additives. Unlike off-the-shelf additives that lubricate the fuel pump and limit their effectiveness to cleaning the injectors, the AXI Fuel Catalyst and Tank Cleaning Additives reverse the long term buildup of sludge and degraded organic materials that have accumulated over time in the tank bottom, removes carbon buildup from engine components and stops the degradation of fuel injectors caused by the acids and degraded fuel components.

The most important part of fuel maintenance is keeping water from entering your tank, and if water does find its way into the tank, remove is as soon as is practicable.

DC-3 Standard Disposable Breather

When fuel is used from a tank, the fuel is replaced with air typically drawn in from the outside of the tank. Moisture and microbes are commonly pulled into the tank with the air. Temperature changes will cause the moisture in the air to condense on the walls of the fuel tank and these droplets of water will eventually find their way to the bottom of the tank. Accumulated water in the tank bottom is the habitat in which the microbes grow. Tanks should be checked at least every sixty (60) days to be assured that water is not accumulating. A Desiccant Fuel Tank Breather presents a good option for preventing water from entering your tank, especially if you are located in a climate with high humidity and wide temperature changes. The Desiccant Tank Breather may be affixed to the vent on the fuel tank providing a simple yet dependable defense against not only particulate contamination from entering the tank, but also moisture in the air from entering the storage or equipment tank.

Water may also enter your tank will fuel fills. This is highly dependent on the attention to tank maintenance practiced by your fuel supplier and other storage facilities upstream from your fuel supplier to the refinery. Some equipment have fuel tanks tucked into confined space and do not provide inspection ports that are easily accessible, nor fill points that allow for access to inspect fuel tank bottoms and determine the presence of water.

WE-12 Water Eliminator

However, tanks that do have easy access should be equipped with a means of capturing and holding water for removal. The Water Eliminator is a highly effective device that is placed in the bottom of the fuel tank and, when fuel is added, may be removed and inspected to determine if any water has entered the tank and captured by the water eliminator device. It is an easy and cost effective means of being assured that your tank is free of water.

Without a place to reproduce, the microbes will float around and eventually be pulled into the fuel flow and routed through the AXI Magnetic Fuel Conditioner, and the microbes will not reproduce and will not adversely affect your engines efficient operation.

If a tank has a straight-line access to the bottom of the fuel tank from the fuel fill hole or through another inspection port, a length of PVC or PEX pipe, 1/2 inch in diameter, can be used like a soda straw to sample what is in the bottom of a tank. Cut the pipe to length to allow insertion of the pipe to the bottom of the tank while allowing your thumb to cover the exposed end of the pipe. With your thumb over the end, insert the pipe to the bottom of the tank, remove your thumb so what is at the very bottom will rush into the tube to the level of fuel in the tank. Again place your thumb over the end of the pipe and extract the pipe, maintaining the liquid and other materials inside the tube. Place an empty clear plastic 2 liter soft drink bottle upright in the bottom of a empty 5-gallon bucket. Direct the end of the tube into the drink bottle (any spilled liquid will be caught inside the five gallon bucket). Perform this action several times. Allow the contents of the bottle to settle (ideally overnight) and inspect the materials in the bottom of the drink bottle. Any debris or water should be apparent.

If your tank is larger and using a tube to recover fuel, water or other debris from the bottom of the tank is not possible, you can use a TS Series Tank Sample Fluid Sampler. You can take 4 oz., 8 oz, or 16 oz. samples using the TS Series Tank Sampler or you can use a hand-held Vacuum Sample Pump (at bottom of the AXI Tank Sampler page) to remove a sample, as described on the Tank Sampler page.

Operating Procedure

Hoses: The intake/suction hose is a clear, see-through reinforced vacuum hose. The return hose is black or blue/black, non-marking, high quality, discharge fuel hose. Both hoses are equipped with quick disconnects or Cam & Groove couplings.

- Attach quick disconnect end of clear suction hose to the quick disconnect Inlet Port of the MTC.

- We highly recommend attaching a straight wand or pipe (cut at an angle at the end that goes into the tank and is at minimum the same inner diameter as the suction hose) to the suction hose to reach the lowest part of the tank bottom.

- Attach quick disconnect end of blue/black discharge hose to quick disconnect Discharge Port 1 of MTC.

- Place the end of the discharge hose in an appropriate-size container (Phase One only). Try to not agitate the fuel in the tank and stir up and disperse water and sediment throughout the fuel –- this will make it more difficult to remove later on.

- For Phases Two and Three, place the end of the discharge hose back in the tank as far away as possible from the suction hose. Ensure that the hose is secured and will not vibrate out of the container when the system is operating.

- Verify that both drain valves are closed and the system is set up in a stable and safe position.

Note: Never restrict the flow on the suction side of an MTC; e.g. by using a smaller ID hose or pipe or attaching the suction hose to a fitting on the tank that has a smaller ID than the hose. This will lead to excessive pump load, noise and ultimately damage the pump.

Phase 1:

We recommend 3 phases to successfully polish a fuel tank. This will ensure all water is removed from the fuel, particulate is removed, and the fuel is in an optimal condition. The goal of Phase One is to remove any free water and sludge on the bottom of the tank without mixing the water into an emulsified state within the fuel. Start the pump motor and be ready to immediately stop it. The vane pump will start pumping as long as the system is primed and the suction lift is not excessive. The flow of fuel can be observed in the see-through suction hose. Watch for a steady flow of fuel into the container.

- Once the fluid begins to fill the discharge container, immediately switch off the motor and inspect the discharged fluid. Resume pumping and continue the above procedure until water and sludge have been removed from tank bottom and primarily fuel is discharged from the return hose.

- To remove as much of the free water and sludge as possible, the suction hose with a straight wand or pipe attached should be placed at the deepest part of the tank. If possible, move the suction hose/pipe to different areas of the tank to more efficiently vacuum the sludge off the bottom. After removing the bulk water and sludge from the tank, switch off the pump. Then, drain all water and debris from the hose and the water separator into an appropriate bucket placed under the drain valve.

Phase 2:

After removing the bulk of the sludge and water from the tank into a separate container for disposal and draining the separator, the return hose is now inserted into the tank. The goal of Phase Two is to remove any additional free water within the tank and also remove any large contaminants and sludge. This phase will clean the fuel and should be a precursor to using the more expensive spin-on filters. It should be noted that meeting required cleanliness codes is typically not possible with pre-filtering alone. Phase Two is used to extend the life of the spin-on filters, and remove the worst of the contaminants, before polishing with fine filters to meet the required cleanliness.

- Insert blue/black discharge hose into tank as far away from the suction hose as possible. In some cases, it is recommended to remove the sending unit cover to gain sufficient access to the tank. In many cases, both hoses will have to be inserted through the same tank fill opening.

- After verifying that both hoses are properly placed in the fuel tank and that the valves on the MTC system are in the correct position, switch on the pump and watch the clear suction hose for fuel flow.

Depending on the amount of contaminant in the tank, we recommend you stop the pump shortly after priming and check for free water and sludge by draining the centrifugal water separator. It may be necessary to depress the air purge valve on top of the separator after opening the drain valve.

Repeating this process and observing the fuel flow will indicate how long the pump should run before it is necessary to drain the separator.

- The MTC should be kept running in the Phase Two recirculating mode until clean fuel samples can be drained from the separator. Then, switch off the pump for final polishing.

- Now is the time to add AFC Series 705 or 710 Fuel Catalyst in a dose of 1 : 2500 (1 gallon of additive to 2500 gallons of fuel). Higher doses of AFC may be necessary depending on condition of fuel.

Phase 3:

Phase Three is the most important phase in meeting specific cleanliness codes. Unlike the pre-filter, the spin-on filters typically use absolute rated media. Absolute filters have a very high efficiency and will ensure that fuel leaving the system is clean to specification and has a low water content. Like previously mentioned, pre-filtering should be performed to remove any large particulate, water, and sludge. Pre-filtering will extend the life of the spin-on filters.

- Connect the return hose to Discharge Port 2.

- Start the pump and the system will run in the re-circulating mode restoring the fuel to its optimal pristine and sparkling condition.

- Monitor the pressure gauge on the filter head. When the pressure reaches 20 – 25 PSI, or reaches the red area it is time to change the filter.

The first time you clean a tank that has not had maintenance performed on it in the past you would circulate the contents of the tank five times. As an example, a 1,000 gallon tank would be circulated five times, running the MTC to circulate a total of 5,000 gallons. The MTC 1000 circulates at a rate of 15 gallons per minute. It would, therefore, require 333 minutes of run time to circulate 5,000 gallons, or 5.5 hours.

As part of a Fuel Management Program, future tank cleaning would be performed periodically based on your experiences from how quickly the fuel requires maintenance. In more humid areas, this tends to be more often. Start will maintenance performed every 4 to 6 months. In dryer geographic areas, this may be extended to 9 to 12 months.

All MTC Systems feature:

- Multi-stage Water Removal, Particulate Filtration, and Fuel Conditioning

- Compact Industrial Design

- Locking Cam and Groove Connections

- Built In Spill Containment Tray

- Primary and Secondary Filtration with By-pass Loop Capability

- Self-Priming Rotary Vane Pumps with Integrated Adjustable Bypass Valve

Mobil Tank Cleaning Series Functionality

MTC Series Mobil Fuel Polishing and Tank Cleaning Systems are designed to efficiently and safely clean and restore fuel to a pristine condition: that condition in which the fuel was the day it left the refinery. Vital to the fuel polishing process, these systems incorporate a multi-stage filtration process that reconditions, stabilizes and decontaminates diesel fuel, bio-fuels, light oils, and hydraulic fluids. All MTC systems are specifically designed for tanks with contaminated fuel that require the removal of water, sediment, and sludge accumulation.

MTC Mobile Fuel Polishing Systems are built with industrial quality components, mounted on either a heavy duty aluminum cart (MTC Series) or a carbon steel skid (MTC-HC Series) with capacities up to 300 Gallons per Minute. All MTC and MTC HC systems feature multi-stage water removal, particulate filtration, fuel conditioning (with the optional Fuel Conditioner on the MTC-X), a compact industrial design locking cam and groove hose connections, built-in spill containment tray, and bypass loop capability. MTC HC systems also offer multiple sampling ports, large contamination holding capacity, robust compact industrial design, liquid-filled vacuum and pressure gauges, Watect water sensor, and Programmable Logic Controllers (PLC) filtration system controllers.

Efficiency is Built In

All MTC Cart and Pallet Mounted Systems are designed and engineered to be highly efficient Tank Cleaning Systems. These recirculating Systems polish, condition and stabilize diesel and bio-fuels, eliminate microbial contamination, and ensure fuel remains clean and dry. These MTC systems are designed to offer the maximum in flexibility and mobility, and, as a critical part of a Fuel Management Program, will keep your tanks clean and your fuel in “Clear & Bright” pristine condition at all times providing maximum efficiency and minimal emissions. The LG-X Series Fuel Conditioner, included on every MTC System (optional on the MTC-X), reverses fuel deterioration and removes sedimentation to sub micron levels, preventing clogged filters, eliminates fuel “algae” issues, extends injection system service life, and reducing smoke, emissions and downtime.

An MTC Series Fuel Polishing System is the central component of a Fuel Management Plan that involves the maintenance of numerous fuel tanks or providing fuel polishing services on a commercial scale to customers over a wide region. Establishing a fuel management and maintenance protocol should include removal of accumulated water, periodic fuel circulation for particulate filtration and polishing of the fuel, and treatment with a Diesel Fuel Treatment and Tank Cleaning Additive such as AFC-705 made to work hand-in-glove with the Fuel Polishing System to clean the fuel tank without removing the fuel, assuring that the lights stay on when the power goes off.

The Fuel Polishing Process

The MTC Series Mobil Tank Cleaning Systems are special-purpose designed two-stage mobile tank cleaning systems. They efficiently decontaminate Diesel Fuel, Bio-Diesel and light Hydraulic Fluid tanks. These Fuel Polishing Systems efficiently remove sludge, water and sediments that naturally accumulate in storage and equipment tanks. The MTC System excels in low operating cost and compact design.

All storage tanks naturally accumulate water, solids and sludge resulting from condensation and the degradation of fuel and oil. Many tanks have not been cleaned or maintained for many years. The MTC Systems are specifically designed to focus on cleaning the worst of the worst contaminated tanks, efficiently removing sludge, debris, and water in the most cost effective means by utilizing Primary, Secondary and sometimes Tertiary Filtration vessels to step down the level of contamination in the tank as the re-circulation of the fuel progresses. Some MTC Mobile Fuel Polishing Systems utilize a centrifuge fuel/water separator capable of removing free water and sludge and debris as the primary filter down to a level of 5 microns. While very capable at sludge and water removal, the cleaning process of badly contaminated thanks will require shutting down the MTC System to empty the centrifuge system and extend operating time significantly.

Many commercial for-hire tank cleaning companies that use the MTC Cart Mounted Systems and face numerous tanks that have never been cleaned before opt to use the PF Series Bag Filter Vessels as a pre-filter, reducing the amount of stop time to drain the Cart System’s primary centrifuge. After the initial cleaning, future maintenance would not require this pre-filter vessel.

Filter bags vessels are used in all of the MTC HC Pallet Systems and the MTC-X Cart Mounted System are inexpensive compared to regular fuel filters (see prices in the tab below for Replacement Fuel Filters) and have greater capacity to accumulate sludge and contaminates before requiring operator attention. Filter bags are available from 800 microns down to one micron. When cleaning very contaminated tanks, it is possible that larger micron bags be emptied and reused several times until they become damaged or sufficiently clogged such that fuel will no long pass through them. This allows for extended use in contaminated tanks with extensive tank bottom contamination.

When the “big pieces” are removed, all MTC Mobile Fuel Polishing Systems have a secondary path that includes Fine Filter removal filters as well as Coalescing and Water Block filters available to remove the water that has emulsified up into the fuel and complete the process of returning the fuel to the “Clear and Bright” state that comes with true Fuel Polishing.

The Fuel Maintenance Program

Generally a fuel preventative maintenance program will require the fuel conditioning and tank cleaning process to include circulating the contents of a fuel tank three times on some periodic basis depending on the quality of incoming fuel and regional climate conditions. The MTC Systems are designed to run until a badly contaminated tank has reached an acceptable level of clean before moving on to the next tank.

The more fuel we put into and take out of a tank the more debris and water will accumulate in the bottom. The MTC Series Fuel Conditioning and Tank Cleaning Systems eliminate the need for costly fuel removal and periodic manual tank cleaning. Stabilizing the fuel and extending the shelf life of the fuel is a critical part of using the MTC Series Mobile Fuel Polishing Systems. This is extremely important for all applications of long-term fuel storage, especially emergency generators.

Applications

The MTC Series Mobile Fuel Polishing and Tank Cleaning Systems are specially designed for cleaning badly contaminated tanks for operations where there are many tanks requiring attention, such as operations with numerous generators in a large campus of offices or industrial facility with many backup power generators, or a farm, construction, or equipment fleet servicing operation that must maintain many tanks, or where facilities are spread over a large geographic region, such as maintaining cell tower backup power or municipal sewage lift stations.

The MTC Mobile Fuel Polishing Systems are ideal for industries such as remote oil/gas drilling operations and processing, cell tower backup power fuel tanks, heavy marine applications such as a tug boat fleet, mining operations, and similar industries. Also, remote resorts, such as island resorts or wilderness resorts where fuel comes in by barge and may be that which others have rejected, would benefit greatly by this equipment.

Additional Information

- Optional LG-X Fuel Conditioner for MTC-X: The MTC-X Cart Mounted Tank Cleaning System is often utilized as a portable fluid transfer pump, and, therefore, not equipped with an LG-X Series Fuel Conditioner in the base unit as are other MTC Mobil Cart Mounted Fuel Polishing Systems. The LG-X Series Fuel Conditioner is an Add-On item for those expecting to perform Fuel Polishing and Tank Cleaning projects with the MTC-X System. Chose the optional add-on Fuel Conditioner when ordering the MTC-X.

- Pre-Filtration: utilizing the PF Series Bag Filtration vessel, and sized to the flow rating of the MTC System, the PF Series Bag Filter will remove major sludge, debris and water from the fuel by trapping extraordinary amounts of sludge, rust, scale and other contaminants upstream before they access the MTC Series Mobile Tannk Cleaning System. The bag filtration media is considerable less expensive than the fine filtration spin-on filters.

- MTC Motor Engine Cover: a steel plate that fits over the motor on the Cart Mounted Tank Cleaning Systems. It protects the motor from damage should the system accidentaly be knocked over during operation or is laid down while being transported from job site to job site.

- Portable Drip/Spill Berm: used with the MTC Cart Mounted Mobile Tank Cleaning Systems, they protect the environment from fuel spillage during the fuel polishing process.

- Suction and Discharge Hose Length Extensions: Sections of hoses may be purchased to service hard-to-reach tanks. Sections are purchased by the foot and Cam & Groove couplings are included. Note that long extensions on the suction side may adversely impact pump performance.

- Caster Wheels for Pallet Mobility: 8″ pneumatic caster wheels for pallet mobility.

- SFC-50 Filtration Controller: an optional Controller for the MTC HC-50, this Controller includes a remote control (pendant switch), & strobe alarm light, and features: programmable, fully automated operations, digital LED text readout, alarms for pump operations, high vacuum and high water levels, easy access alarm reset, optional manual operation, and BMS / BAS Interface.

- Dual Inlet Port Accessory: for complete control of a second suction inlet hose in addition to the main inlet hose while the main inlet hose recirculates the large majority of fuel. The smaller, more manageable 1″ hose, makes reaching difficult areas easier to reach and allows personnel access to smaller tank ports and openings. Available for the MTC HC-90 and MTC HC-150.

- Alarm Strobe: provides flashing light signal that System shut down and maintenance service is required.

- Audible Alarm: provides audible signal that System shut down and maintenance service is required.

- Replacement Filter Bags (Size #1): for the Systems that use the PF-30 HD Bag Filter Vessel as the Primary Filter (MTC X, MTC HC-50, & MTC HC-90

- Replacement Filter Bags (Size #2): for the MTC HD-150, & MTC HC-300

- Replacement Spin-On Filters: for the MTC-1000, & MTC-X

- Replacement Filter Cartridges: for the FV-120 Filtration Vessel that requires one cartridge – MTC HC-50, MTC HC-90, & MTC HC-150, & four cartridges – MTC HC-300

Pricing Information for the MTC Series Mobile Fuel Polishing and Tank Cleaning Systems

The MTC Series Mobile Tank Cleaning Systems consist of cart mounted Systems and pallet mounted systems. The online shopping cart can calculate shipping charges on orders that have a combined Shipping Weight of under 150 pounds. As all MTC Fuel Maintenance Systems exceed this weight, orders for these systems must be handled manually. Contact us for additional information, a full quote for a system to meet your requirements, or to place an order for any of the Cart Mounted or Pallet Mounted MTC Series Fuel Maintenance System.

Pricing for the Cart Mounted and Pallet Mounted MTC Series Systems are provided below in this page column.

Note that optional and add-on equipment, listed in the Additional Information section for both the MTC Cart Systems and MTC HC Pallet & Skid Mobile Systems may be purchased using the links provided to enter the Shopping Cart for ordering these items.

MTC 1000 – Cart Mounted Mobile Fuel Maintenance System – 900 GPH

Click Image to Enlarge

MTC 1000 -LX S110-60 — 900 GPH 120V/60Hz/15A – 1″ Cam & Groove Ports – Multi-Stage Filtration – Base Price: $13,321.77

MTC 1000-LX S230-50 — 900 GPH 230V/50Hz/15A – 1″ Cam & Groove Ports – Multi-Stage Filtration – Base Price: $13,321.72

See the Drop Down Menu on left side of this page for full specifications.

MTC-X – Cart Mounted Mobile Fuel Maintenance System – 1,560 GPH

Click Image to Enlarge

MTC-X S110-60 – 1,560 GPH Nominal Flow Rate – 120V/ 60Hz – 1-1/2″Suction & 1 1/4″ Discharge Cam & Groove Ports – Multi-stage Filtration – Base Price: $18,288.71

MTC-X S110-60 w/LGX 3000 – 1,560 GPH Nominal Flow Rate – 120V/ 60Hz – 1-1/2″Suction & 1 1/4″ Discharge Cam & Groove Ports – Multi-stage Filtration – Including the optional LG-X 3000 Fuel Conditioner (Recommended) – Base Price: $19,825.72

MTC-X S230-50 – 1.248 GPH Nominal Flow Rate – 230V/50Hz – 1-1/2″Suction & 1 1/4″ Discharge Cam & Groove Ports – Multi-stage Filtration – Base Price: $18,288.71

MTC-X S230-50 w/LGX 3000 – 1.248 GPH Nominal Flow Rate – 230V/50Hz – 1-1/2″Suction & 1 1/4″ Discharge Cam & Groove Ports – Multi-stage Filtration – Including the optional LG-X 3000 Fuel Conditioner (Recommended) – Base Price: $19,825.72

Note: When utilizing the MTC-X Cart Mounted System for the purpose of fuel transfer, the need for a Fuel Conditioner is reduced. However, if the MTC-X is to be used for cleaning fuel tanks and polishing fuel that is stored for long periods, such as for backup diesel generator systems, inclusion of the LG-X 3000 Fuel Conditioner is highly recommended.

See the Drop Down Menu on left side of this page for full specifications.

MTC HC50 – Pallet Mounted Mobile Fuel Maintenance System – 1,500 to 4,500 GPH

Click Image to Enlarge

MTC HC-50 – Pallet Mounted Mobile Fuel Maintenance System – 3,000 GPH – Air Powered (25-50 SCFM @ 90 psi) – Air Driven Double-Diaphragm Pump – Base Price: $35,495.37

See the Drop Down Menu on left side of this page for full specifications.

MTC HC-90 – Pallet Mounted Mobile Fuel Maintenance System – 600 to 5,400 GPH

Click on Image to Enlarge

MTC HC90 – 90GPM High Capacity Mobile Fuel Polishing System – 208-230V/60Hz 1 Phase Input Voltage – Variable Flow/Vane Pump/25′ Hoses 2″Diameter w/cam & groove connections – Mobus TCP-IP – Base Price: $51,855.82

MTC HC90 – 90GPM High Capacity Mobile Fuel Polishing System – 230V/50Hz 1 Phase Input Voltage – Variable Flow/Vane Pump/25′ Hoses 2″Diameter w/cam & groove connections – Mobus TCP-IP – Base Price: $51,855.82

MTC HC90 S240-60 – 90GPM High Capacity Mobile Fuel Polishing System – 240V/60Hz 3 Phase Input Voltage – Variable Flow/Vane Pump/25′ Hoses 2″ Diameter cam & groove connections – Mobus TCP/IP – Base Price: $52,666.14

MTC HC90 S240-60 – 90GPM High Capacity Mobile Fuel Polishing System – 480V/60Hz 3 Phase Input Voltage – Variable Flow/Vane Pump/25′ Hoses 2″ Diameter cam & groove connections – Mobus TCP-IP – Base Price: $52,666.14

See the Drop Down Menu on left side of this page for full specifications.

MTC HC-150 – Pallet Mounted Mobile Fuel Maintenance System – 600 to 5,400 GPH

Click on Image to Enlarge

MTC HC150 S480-60 – 150GPM High Capacity Mobile Fuel Polishing System – 480/60Hz/ 3 Phase- Variable Flow/Vane Pump/25′ Hoses 3″ Diameter cam & groove connections – Mobus TCP-IP – Base Price: $87,037.62

See the Drop Down Menu on left side of this page for full specifications.

MTC HC 300 – Skid Mounted Mobile Fuel Maintenance System – up to 300 GPM – 18,000 GPH

Click on Image to Enlarge

MTC HC300 S480-60 – 300GPM High Capacity Mobile Fuel Polishing System – 480VAC, 50HZ/60Hz 3Phase – Variable Flow/Vane Pump/25′ Hoses 4″ Diameter cam & groove connections – Mobus TCP-IP – Base Price: $201,812.22

See the Drop Down Menu on left side of this page for full specifications.